Surface Finish and Mechanical Properties of FDM Part After Blow Cold Vapor Treatment

Keywords:

3D printing, Fused Deposition Modeling, Vapor treatment process, Additive ManufacturingAbstract

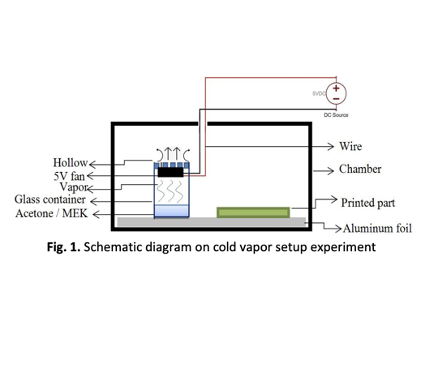

Fused deposition modeling (FDM) is a 3D printing/additive manufacturing (AM) technology that creates a part layer by layer. However, the printed parts have poor surface finish and staircase effect, which is the inherent characteristics of FDM printed parts. This contributes to poor quality of the final components. Thus, in this paper, post process treatment on 3D printed part by using blow cold vapor has been made. The parts were fabricated by using the open-source 3D printer with acrylonitrile-butadiene-styrene (ABS) material. Then, after the treatment, the surface finish and the mechanical properties of the parts were analyzed. The cold vapor treatment using chemical agents, namely acetone and methyl-ethyl-ketone (MEK). A comparison was made between the parts before and after treatment. It is found that the proposed method is able to improve the surface finishing of FDM parts. However, the method has affected the tensile strength where there is a slight decrease in the strength value.

Downloads