Design and Fabrication of Jig and Fixture for Drilling Machine in the Manufacturing Industry to Improve Time Productivity

DOI:

https://doi.org/10.37934/araset.29.2.304313Keywords:

Jigs and fixture, Drilling machine, Drilling process, Machining time, Time productivityAbstract

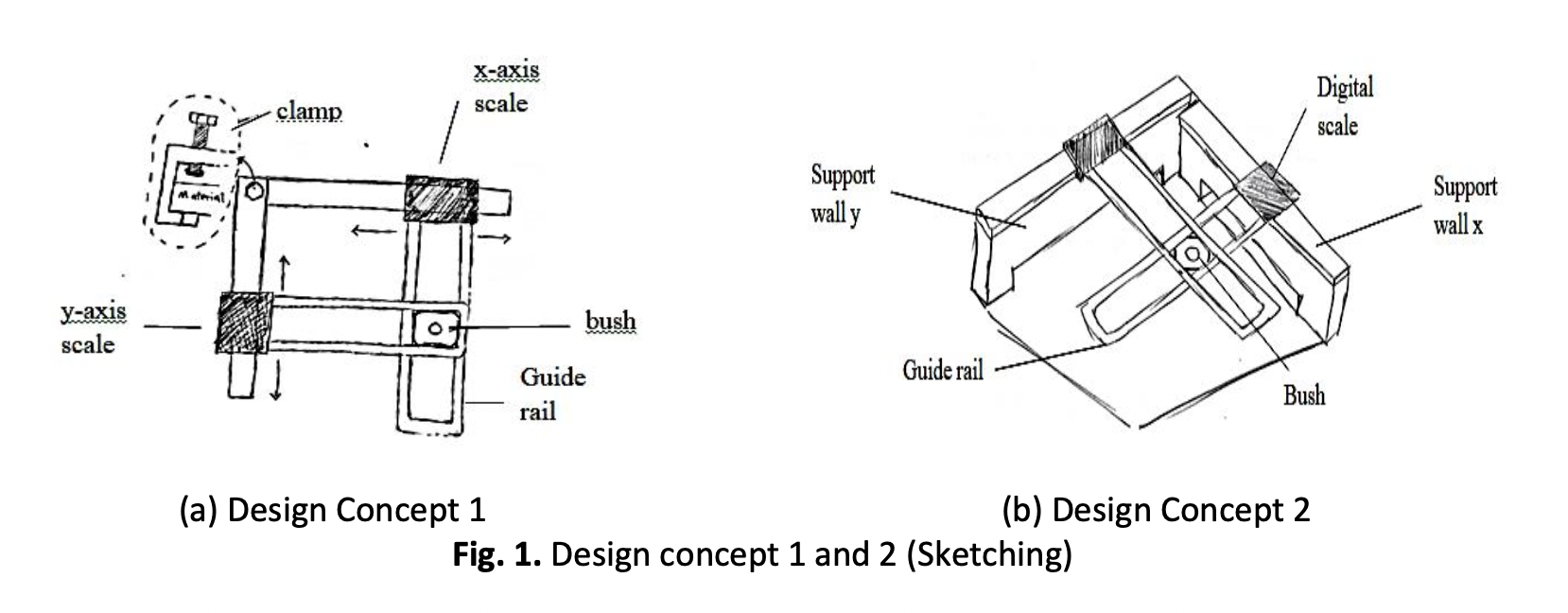

Jigs and fixtures were brought to the world of machining, bringing a variety of practical purposes. The concept enables rapid mass production of the same product. Thus, the company will streamline the manufacturing process for each component and boost productivity. At times, the machining operation was carried out entirely by the machine, without jigs and fixtures. As a result, jigs and fixtures were created to expedite the drilling process. The project's objectives are to design a jig and fixture, fabricate it, and analyze the performance on a square block of wood. The structural model for drilling jigs and fixtures was created using the Inventor Professional 2019 Computer-Aided Design Software. The fabrication process used were milling, surface grinding, CNC wire-cut, and drilling machines. Aluminium 1065 was utilized because it is less expensive, lighter than other materials, and easy to process. The result demonstrates that a hole can be drilled quickly using the jigs and fixtures. Preparing the hole with a jig and fixture takes only 1.28 minutes, compared to 3.45 minutes with a table drill. The advantages of this product are the time operation can be reduced and quickly operations on the drilling process.

Downloads