Production of Washed Bottom Ash as Sand Replacement Material in Concrete Paving Block

DOI:

https://doi.org/10.37934/araset.29.2.236250Abstract

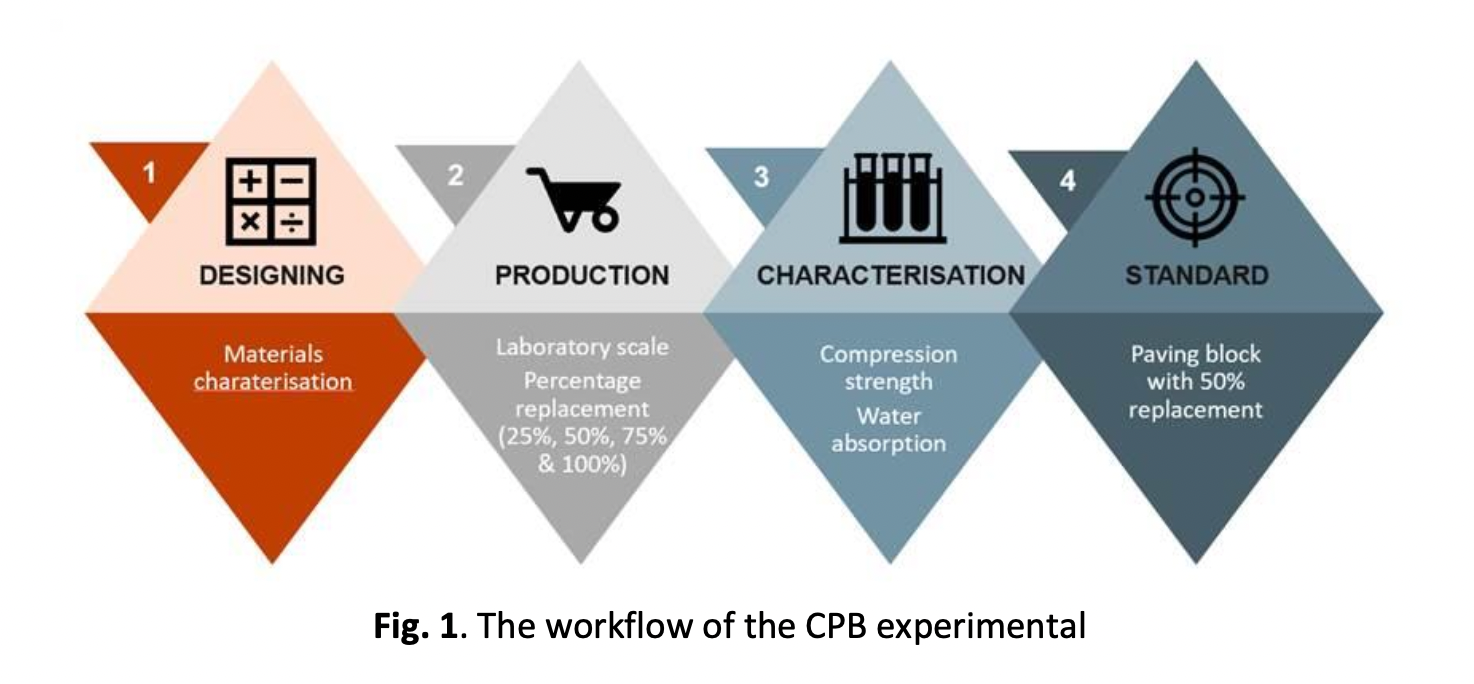

Concrete Paving Block (CPB) is made by mixing sand, gravel, cement, and water and is used in non-traffic and traffic areas. The CPB is proposed in a variety of shapes, sizes, colours, and materials. The demand for the CPB is increased in line by increasing in residential houses and building construction, and infrastructure activity. The advantages of CPB when compared with the rigid and flexible pavement is a more beautiful and interactive surface, fast-paced production without high technology equipment or skilled worker, and also creating a balanced humidity. Nowadays, concrete using waste materials such as cement, sand, or gravel replacement becomes more popular which supported the sustainable development requirement and goal. The replacement activity of concrete ingredients for promoting waste material with low carbon content in CPB is also part of the sustainable development programme which reduced the environmental impact of the waste material or production of natural concrete ingredients and cost production. With the intention of the issue, the CPB using bottom ash (BA) which is washed to reduce the carbon content is produced and tested for skid resistance, water absorption, and mechanical behaviour. The chemical and physical behaviour of WBA is conducted and shown the suitability to replace sand in CPB. The compressive strength of WBA with 100% of sand replacement in CPB illustrates the maximum load and compressive strength of approximately 1198.35 kN and 30.73 MPa and is appropriately used for paving blocks.

Downloads