Experimental Investigation on Mechanical Characterization, Ranking and Water Absorption Behavior of RHA/WDA/RHAWDA Filled Epoxy Based Glass Fiber Reinforced Hybrid Composites

DOI:

https://doi.org/10.37934/araset.33.1.1019Keywords:

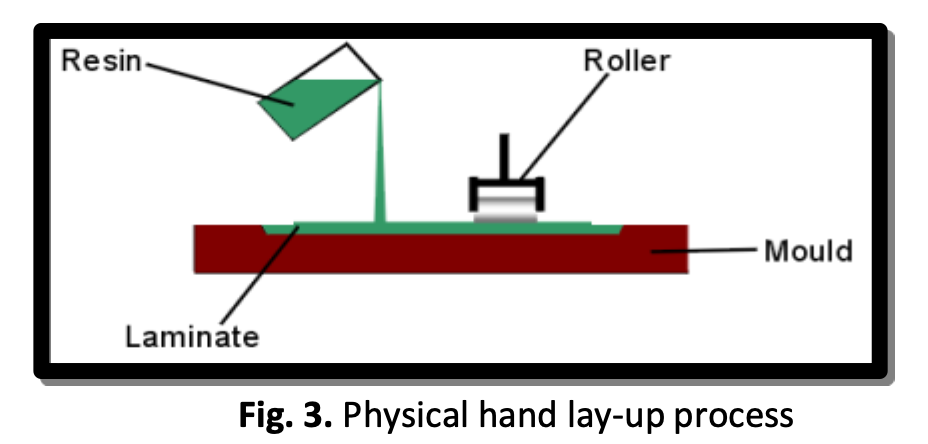

Industrial wastes, natural fillers, reinforcement, matrix, physical hand lay-up procedure, composite slabs, standards of ASTM, mechanical characterization, water absorption rate (WA)Abstract

In the present research work, a novel class of epoxy built hybrid combinations strengthened with E-Glass woven rowed mat and occupied with rice husk ash (RHA), wood dust ash (WDA) and a mixture of RHA & WDA has been developed and structural mechanical properties were determined and the results were matched with the non-filled composites. The studies on these composites reveal that the tensile strength (TS) of the composites is decreased by the escalation in weight percentage of the filler material and the rest of the mechanical properties were increased with the increase in weightiness proportion of RHA, WDA and RHAWDA. TOPSIS and VIKOR’S ranking methods are applied to know the best composite from 16 alternative composites having 6 attributes. From the results, the composite filled with RHA at 5 wt% is selected as the best composite based on mechanical characteristics. Water absorption behavior of the composites at various time intervals for RHA, WDA and RHAWDA filled hybrid composites has been studied and it is concluded that the composites occupied with RHA at 12.5 wt% have given the minimum water absorption rate (WA) compared to other filled composites immersed in distilled and mineral waters and the composite filled with WDA at 2.5 wt% has exhibited the minimum water absorption rate (WA) when it is immersed in ground water for 144 hours of a time interval. Based on the results of water absorption rate (WA) and mechanical characteristics (impact strength and Vickers hardness) the composites filled with RHA at 5 wt% and RHA at 12.5 wt% can be used for the manufacturing of roof sheets and water tanks.

Downloads