Influence of Palm Kernel Shell on Mechanical Properties on The Achievement of Kernelrazzo Concrete Floor Finish Production

DOI:

https://doi.org/10.37934/araset.30.1.5064Keywords:

Kernelrazzo, Marble chippings, Palm kernel shell, Compressive strength, Flexural strength, Epidemic, Quarry dustAbstract

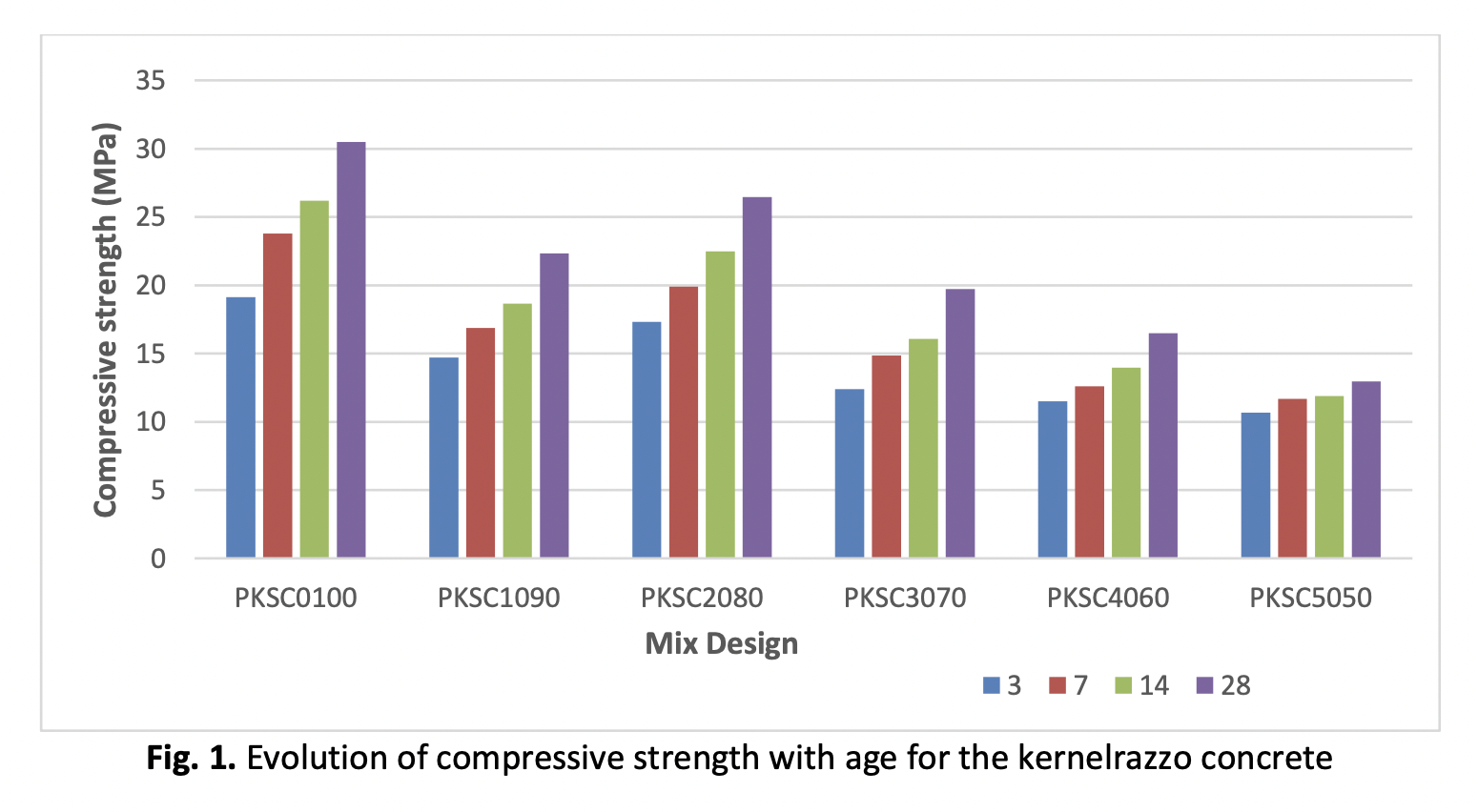

The purpose of this research report is to disseminate the findings of a study on the consequences of palm kernel shell on the mechanical properties of kernelrazzo concrete floor finishes made using the Department of Environment (DoE) design method combinations of cement, quarry dust, as well as palm kernel shell in place of some marble chippings. The use of palm kernel shell, which is readily available as a coarse aggregate substitute, is the only option allowed for this research project to minimize the self-weight or dead load of the floors and to cut the cost of construction. Quarry dust was used as a fine aggregate, while marble chips and palm kernel shell were used as coarse aggregates. There were six distinct concrete mixtures created, and it is significant to note that, when considering the degree of workability values, the results of their slump tests are quite good. The possible significance of this research is that just 19 mm granite with a water-cement ratio of 0.5 was obtained at 28 days, the compressive strength grade of 30.50 N/mm2, 22.32N/mm2, 26.46 N/mm2, 19.72N/mm2, 16.47N/mm2 and 12.96N/mm2 respectively while flexural strength concrete grade of 5.44 N/mm2, 3.85N/mm2, 4.56 N/mm2, 3.01N/mm2 and 2.46N/mm2. There is no result at 50% palm kernel shells, concrete is good in compression but weak in tension. The research work's contribution to knowledge is in the awareness it provides regarding the potential use of agro-waste materials, prevention of epidemic and other related diseases that may arise from waste palm kernel shells and source of income generation and reduction of economic loss that may result from early kernelrazzo concrete floor finishes failure in urban and rural communities, in yards for offices and factories due to incorrect concrete proportioning with a maximum of 33% quarry dust and 20% palm kernel shell replacement with marble chippings.

Downloads