Performance Evaluation of Electrode Fabricated by using FDM in Die-Sinking EDM

DOI:

https://doi.org/10.37934/araset.34.3.129142Keywords:

EDM, FDM, metallization, RTAbstract

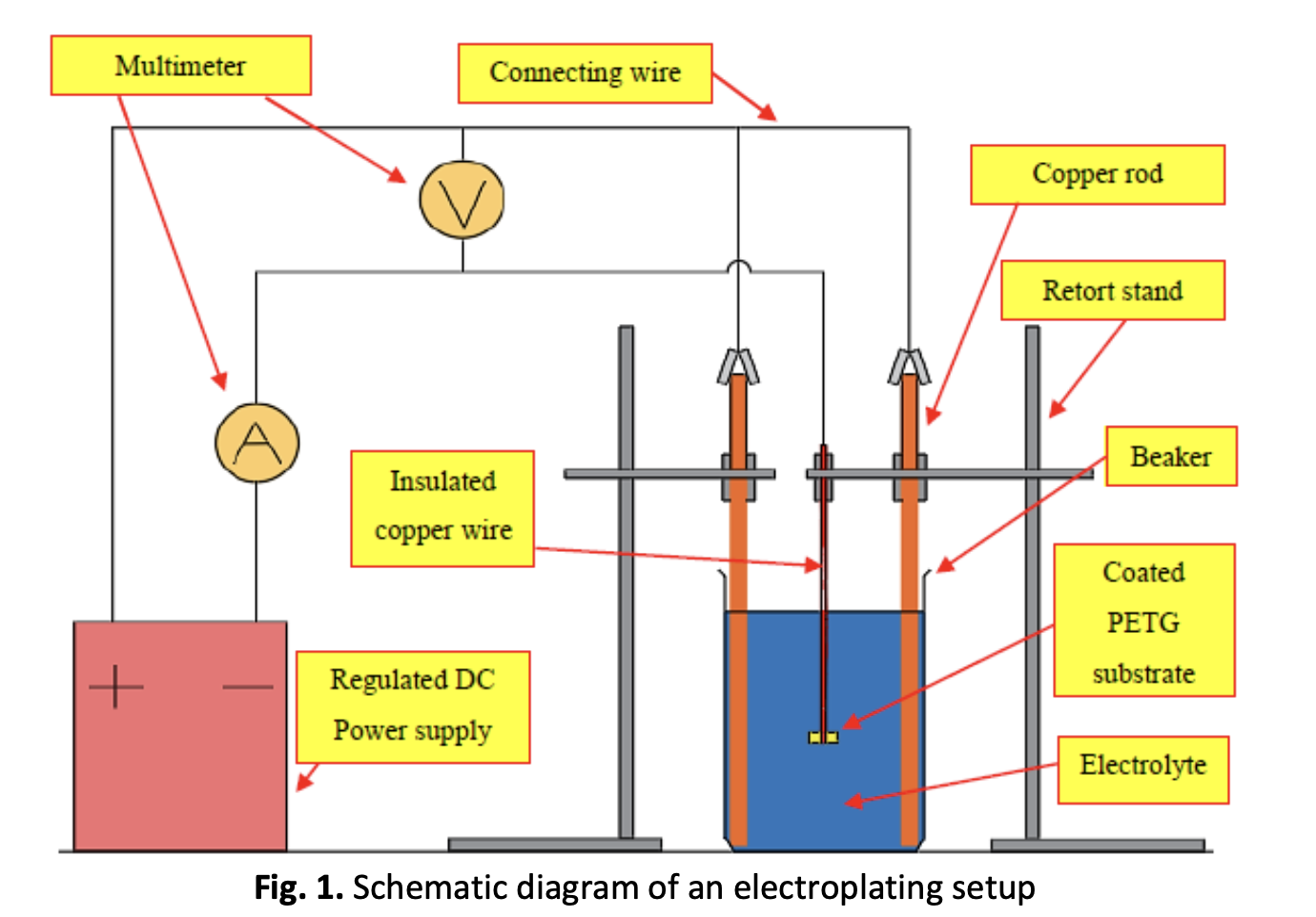

An electrode is a vital transmission tool of electrical charges that erodes a workpiece surface in die-sinking electrical discharge machining (EDM). However, the demanding requirements of the geometrical complexity and accuracy of an electrode significantly affected its manufacturing cost and time. Therefore, rapid tooling (RT) was attempted to improve electrode manufacturing. This research aims to verify the application of the FDM electrode in die-sinking EDM. Furthermore, the metallization and the machining performance of the FDM electrode were also studied. Fused Deposition Modelling (FDM) was utilized to fabricate a cylindrical electrode core made of Polyethylene Terephthalate Glycol (PETG). In primary metallization, the electrode core was immersed in copper paint. Next, the coated PETG substrate was electroplated in secondary metallization at a current density of 0.023 A cm-2 for 168 hours (7 days). The electrolyte consists of 80 g/ℓ copper (II) sulphate pentahydrate and 20 ml/ℓ sulphuric acid. The machining performance of FDM electrode such as material removal rate (MRR), electrode wear rate (EWR) and surface roughness (SR) was benchmarked with a copper electrode. Copper coating with an average thickness of 334 µm was successfully electroplated on the surface of the FDM electrode. Additionally, the FDM electrode was able to machine the mild steel workpiece with 1 mm infit at a peak current of 16 A and pulse-on time of 50 µs without suffering premature electrode failures such as edge failure, delamination, distortion and rupturing. Lastly, the machining performance of the FDM electrode was comparable to the copper electrode in terms of MRR, EWR and SR. The potential of the FDM electrode in EDM machining is proven successful and can be investigated further to enhance the performance of this electrode.