Analysis of Food Holder Design Parameters based on Fused Deposition Modelling (FDM) using Design of Experiment Method

DOI:

https://doi.org/10.37934/araset.34.1.133141Keywords:

3D printing, food manufacturing, Design of Experiment, filling machine, food holderAbstract

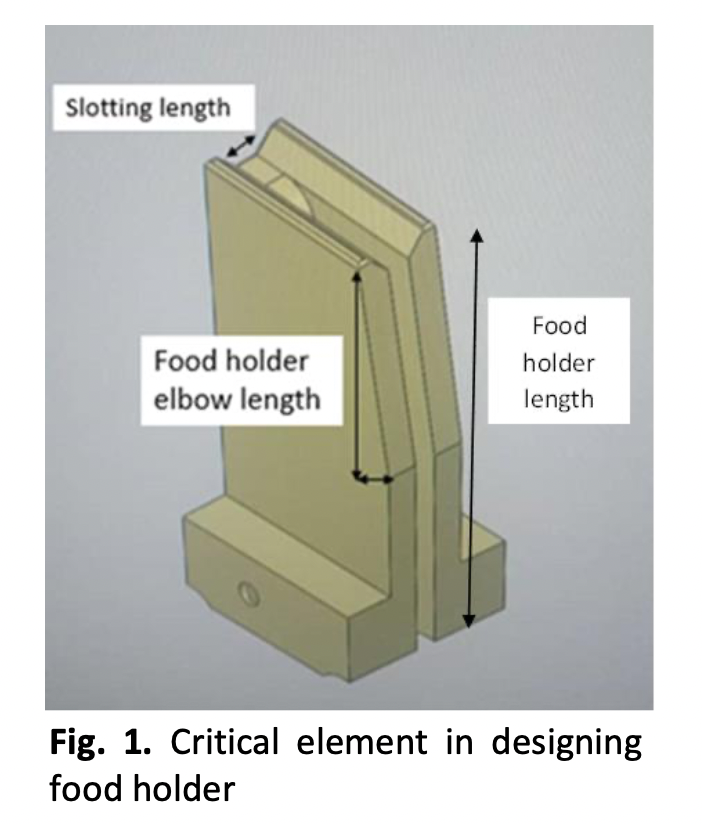

The limitations of food holders available in local food manufacturer companies make it difficult to produce varieties of the food pouch size. Since each size of the pouch requires a specific size of food holder, therefore, this paper aims to analyze and design of a new food holder for a food pouch with a 500g capacity to be used in the filling machine. The pouch, conveyor, and ball plunger were analyzed to help in designing the food holder. Then, critical criteria were identified such as the food holder’s height, elbow length, and slotting length. After analyzing all the critical criteria, the design of experiment method (DOE) was used to identify significant parameters in designing the food holder. A dry run was done to test the holder, and as a result, it was identified that the food holder height was the most significant criteria, but other criteria also played an important role in the food holder.

Downloads