All Solution Processable OTFT-Based on Direct-Written Printing Method Towards Flexible Electronics Applications

DOI:

https://doi.org/10.37934/araset.41.2.93101Keywords:

Organic thin film transistor, Direct-write printing, TIPS-PEN, Semiconductor devicesAbstract

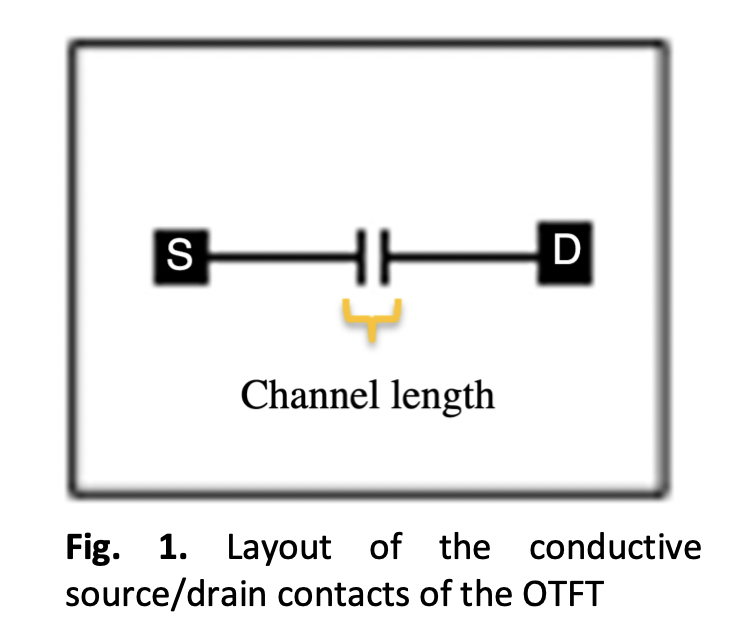

Development of organic electronics, particularly organic thin film transistors (OTFTs), have been centred of discussion among researchers due to their potential uses in flexible electronics applications. Conventionally, an inkjet printing method has been deployed to fabricate the OTFTs due to its simplicity in fabrication steps and applicability to diverse substrates and solution-processable materials. Nonetheless, this technique has a major drawback which requires low viscosity materials to prevent clogging issue at the printer’s nozzle. This in return limits the material selections and requires additional steps i.e. modification of the selected materials to fit the printer’s requirement or in other words, to avoid clogging at the nozzle. Therefore, this paper proposes a method to fabricate a bottom gate bottom contact (BGBC) OTFT by using a direct-write printing technique which is compatible with a commercial conductive ink that can be directly used without any further modification. This technique does not compromise the fabricated devices overall performance and can fabricate the devices up to micrometre scale. The proposed OTFT achieved a saturation mobility of 4.28x10-5 cm2/Vs, a threshold voltage of -0.4 V, an on/off current ratio of 102, and a subthreshold swing of 10 V/dec with overall fabrication temperature is less than 150 ℃, hence, makes it suitable for flexible electronics applications.

Downloads