Study of the Effects of Five Different Machining Fluids on the Surface Hardness and Corrosion Behaviour of Al6061 Alloy

DOI:

https://doi.org/10.37934/araset.42.2.7288Keywords:

Al6061 alloy, Corrosion, Machining fluids, Surface hardnessAbstract

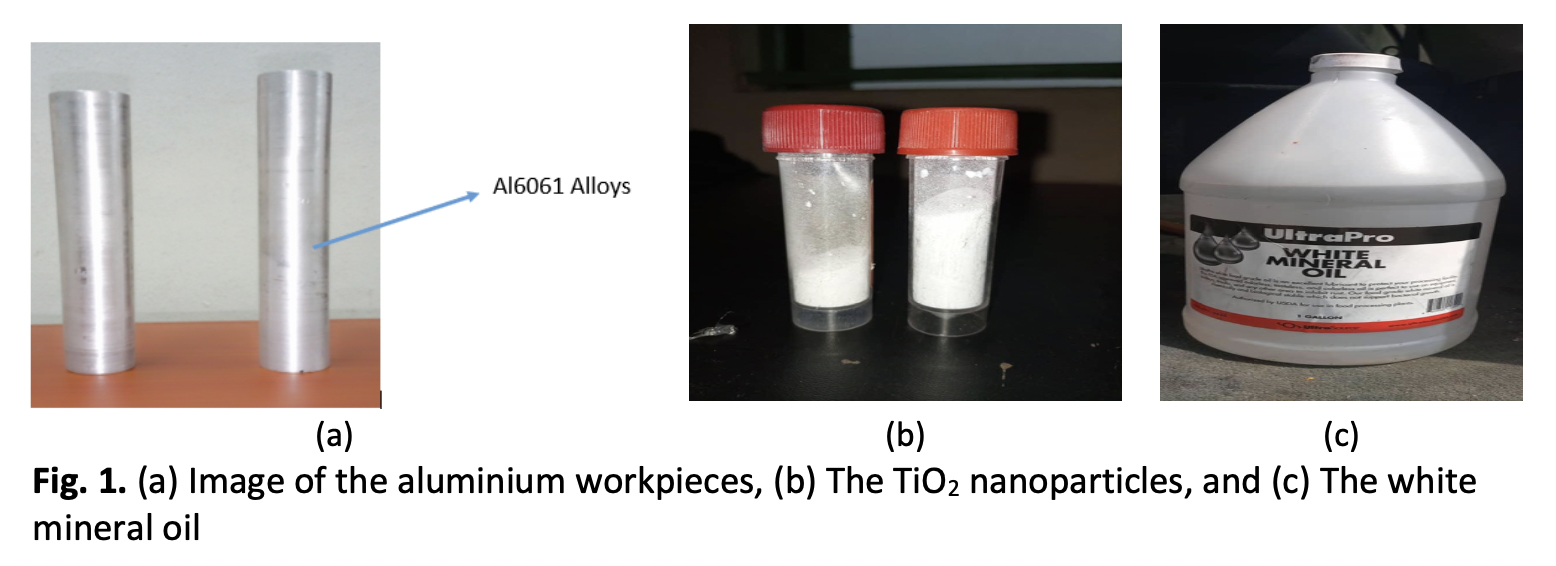

The effects of various machining fluids on the surface hardness and corrosion behaviour of Al6061 alloy were investigated in this study. The study employed the two-step method to develop the machining fluid containing TiO2 nanoparticles with various percentage concentrations. The corrosion study media consist of soluble oil (sample A1), mineral oil (sample A2), 0.2-g/l-TiO2 nano-mineral machining fluid (sample A3), 0.4-g/l-TiO2 nano-mineral machining fluid (sample A4) and 0.6-g/l-TiO2 nano-mineral machining fluid (sample 5). The corrosion study was carried out with Potentiodynamic corrosion and polarisation resistance techniques. After the corrosion study, the SEM and EDS were employed to investigate the microstructure and elemental composition of the machining fluid effects on the Al6061 alloy, and the Vickers micro-hardness machine was used to test the surface hardness of the normal face region that was exposed to the corrosion study. The results show that the soluble oil has a high corrosion rate, with the list polarisation resistance rate compared to the other machining fluid employed in this study. Furthermore, the 0.6-g/l-TiO2 nano-mineral machining fluid has the lowest corrosion rate of 0.115 (µm/year) and the highest polarisation resistance of 1.543 (MΩ). The study concluded that the 0.6-g/l-TiO2 nano-mineral machining fluid is viable for the machining process.

Downloads