Characteristics of Heterogeneous Catalysts Fly Ash Fraction of Light Shell and Fiber of Palm Oil Mill Solid Waste Grown on Peatlands

DOI:

https://doi.org/10.37934/araset.28.3.85104Keywords:

Biodiesel, calcination, catalyst, light-fraction ash, palm oilAbstract

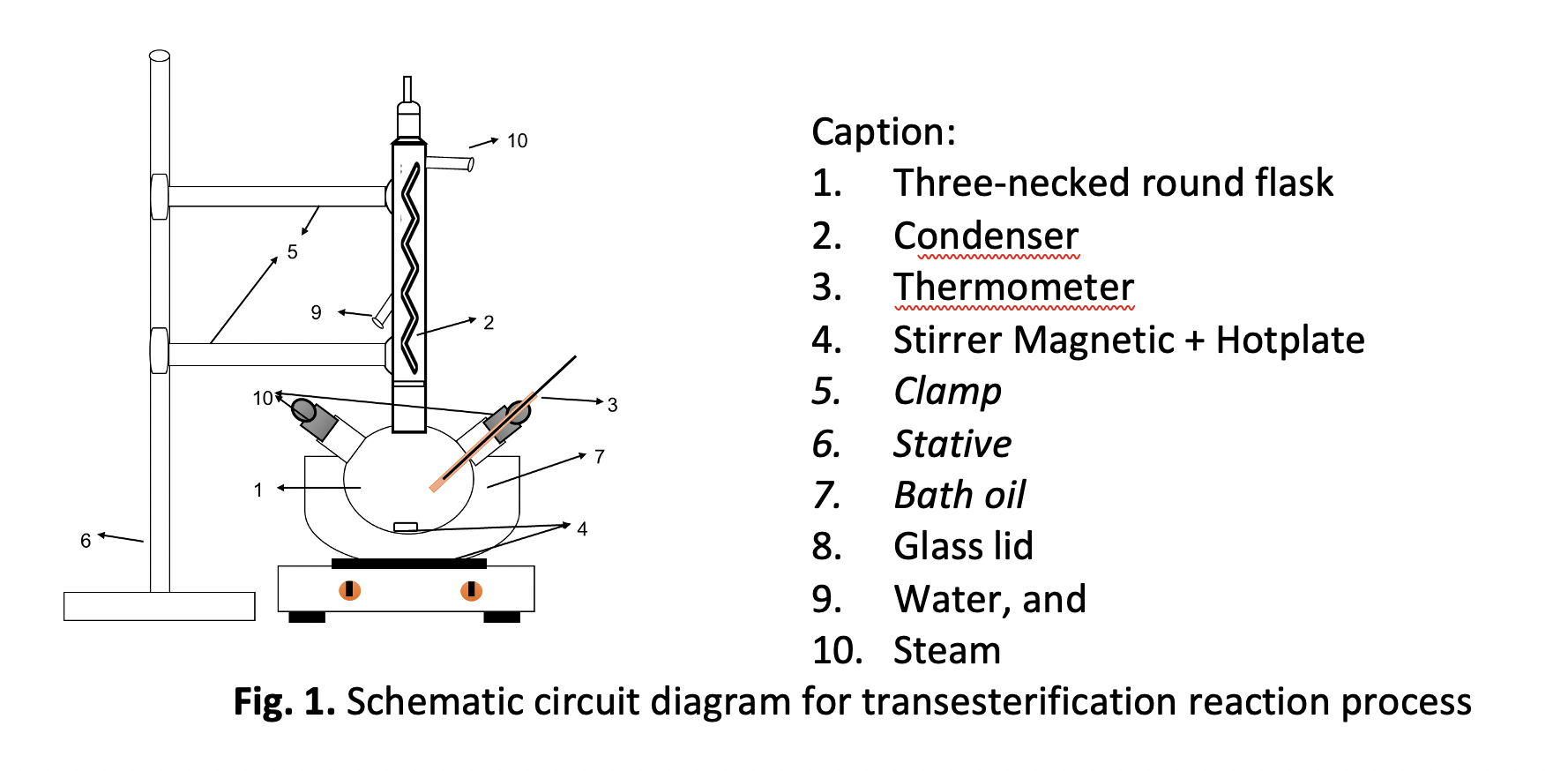

Utilization of biomass from agricultural waste in Indonesia is still not optimal. Biomass from agricultural waste containing of Si and Ca can be used for the manufacture of heterogeneous base catalysts. The catalyst produced will be applied to the manufacture of biodiesel. A biodiesel quality test and Gas chromatography-mass spectroscopy (GC-MS) test are carried out, including chemical composition analysis test (X-RD), three-dimensional structure (SEM), material characterization (FT-IR), surface and basic properties (BET), and mass-weight change (TGA). The research method used is an experimental method, where this research was carried out in 3 stages; the first stage is to determine the test and characteristics of crude palm oil raw material, the second is on the manufacture of palm ash catalyst, and the third is the application of a heterogeneous catalyst based on palm fly ash in the manufacture of biodiesel. The results on the characteristics of crude palm oil after purification using 5% shell activated charcoal showed an increase in quality, including the number of free fatty acids 3.86% w/w, water content 0.0015%, impurities content 0.0485%. The acid number of 13.840mgKOH/g is still within the quality standard, while for the quality of the biodiesel produced, the calcination catalyst treatment at a temperature of 700ºC for 5 hours for the density parameter is 0.860g/ml, water content is 0.03%-wb, iodine number is 26.30gI2/100g, saponification number 90.88mgKOH/g, and free fatty acid number 0.38%w/w have values according to biodiesel standard ASTM D6751. Catalyst calcined at 700ºC 5 hours found mesopore (7.93 nm) with a surface area 25.288 m²/g. It also has CaO around 36º peaks, where catalyst particles are spherical with a smooth surface.Downloads

Downloads

Published

2022-11-30

How to Cite

Susanto, A., Abdullah, Muthia Elma, & Meilana Dharma Putra. (2022). Characteristics of Heterogeneous Catalysts Fly Ash Fraction of Light Shell and Fiber of Palm Oil Mill Solid Waste Grown on Peatlands. Journal of Advanced Research in Applied Sciences and Engineering Technology, 28(3), 85–104. https://doi.org/10.37934/araset.28.3.85104

Issue

Section

Articles