Improvement of Cork Insulating Properties using Ecological Treatment with Prediction of the Diffusion Coefficient by ANN Approach, under the Effect of the Area and the Direction of the Cut

DOI:

https://doi.org/10.37934/arfmts.109.1.177187Keywords:

Cork, THT, diffusion coefficient, modelisation, optimisation, ANNAbstract

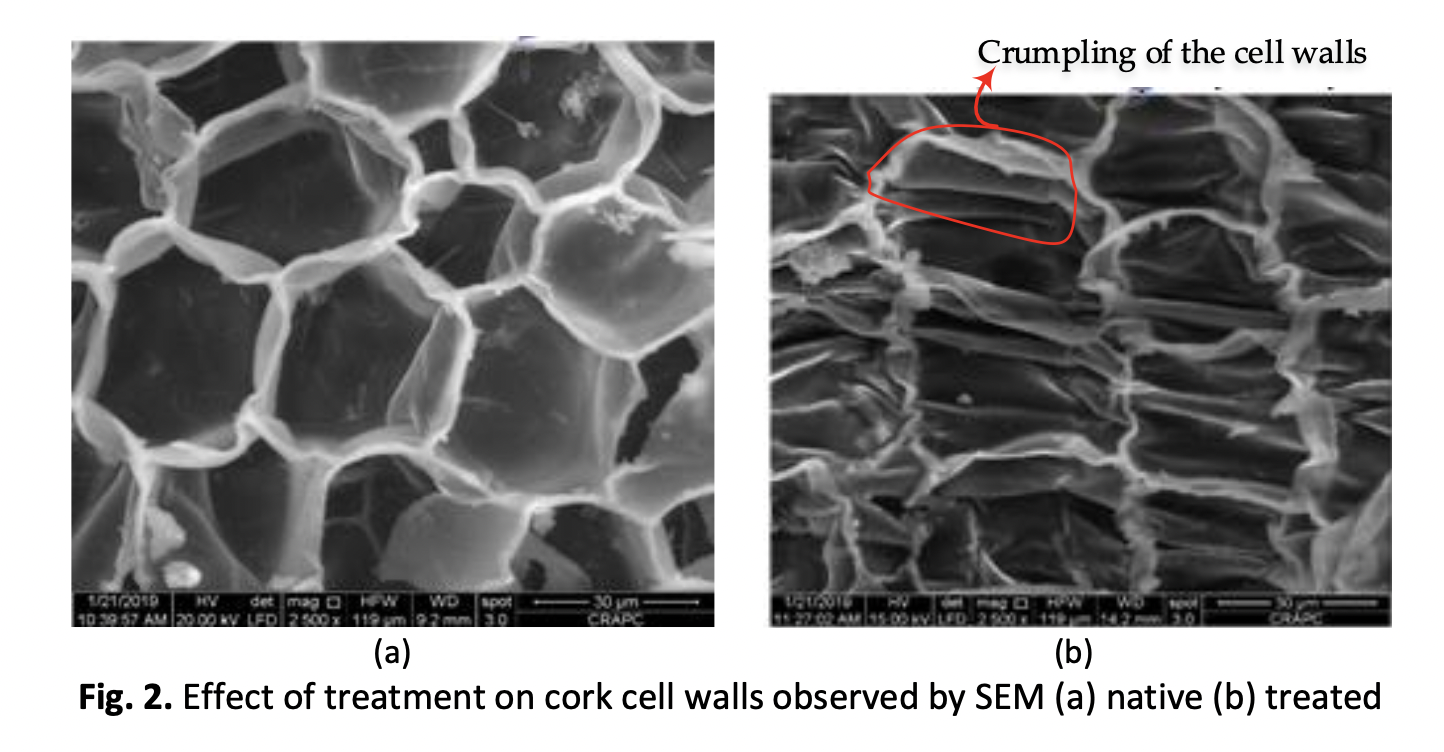

The significance of this work involves improving the mechanical characteristics of cork with a high temperature treatment (THT) ecological treatment taking into consideration different parameters such as the growing area (Medea, Jijel and Skikda), the cutting direction (radial, tangential and longitudinal) and the nature of samples (native and treated). The THT result in the modification of the transport properties particularly the cork mass diffusion coefficient. The value of the apparent diffusion coefficient that best fit the experimental data was evaluated by the calibration of the developed mathematical model results. Thus, it can be concluded that the heat treatment led to a very significant improvement in the diffusion coefficient for treated cork that is grown in Jijel area and cut in the tangential direction. To refine the calculations, all the obtained results were optimized by the Bat-algorithm. The apparent coefficient diffusion ranges from DJTn=3.05x10-12m2s-1 to DJTt=1.17×10-13m2s-1, is determined with a root mean square error of 10-5. Furthermore, this investigation was completed by developing an artificial neural network model (ANN) in order to predict the impact of the different parameters on the apparent coefficient diffusion. Indeed, the results mentioned above have been confirmed by the neural network of an optimal architecture of (5-5-13-1) with a correlation coefficient value is equal to 0.9995.

Downloads