Coal Flowability Control on Preventing Spillage on Conveyor Belt through Modeling and Simulation for Improving its Performance

DOI:

https://doi.org/10.37934/arfmts.90.1.130145Keywords:

Settling zone, DEM simulation, controlling flowability, optimizing conveyorAbstract

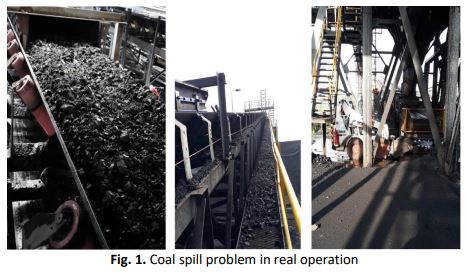

Belt conveyors are generally used in mining plant areas, both surface and underground mines. The belt conveyor is mainly applied to transport the extracted bulk material from the mining site to delivery. The effectiveness of the extraction process depends on the reliability and durability of the conveyor belt system. In addition, conveyor performance is very important specially to control material flowability to prevent spills or other operational disturbances to optimize production throughput. However, the transfer chute and settling zone can cause some problems during the transfer process, such as material spills. This problem can reduce the function and performance of the conveyor belt. This paper discusses a design model to reduce the problem of spillage in the settling zone. The model was developed by compiling the previous defecting data from the durability of the conveyor system, then analyzed using Discrete Element Method (DEM) software and compared with bulk characteristics. The initial performance of certain conveyors is only capable of serving with an average production of 76% of the designed capacity while energy is consumed at full load. By applying the DEM simulation result, the blade gate can reduce the peak angle break in the depositional zone before exiting. After the analysis is completed using DEM, the conveyor increases the average production to 95% of the designed capacity. In conclusion, controlling the maximum belt load without spillage will reduce interruption on conveyor belt operation and maintenance costs therefore increase plant reliability and availability.

Downloads