Risk Assessment of Solid Propellant Rocket Motor using a Combination of HAZOP and FMEA Methods

DOI:

https://doi.org/10.37934/arfmts.110.1.6378Keywords:

Solid-propellant Rocket Motor (SRM), Risk assessment, HAZOP, FMEAAbstract

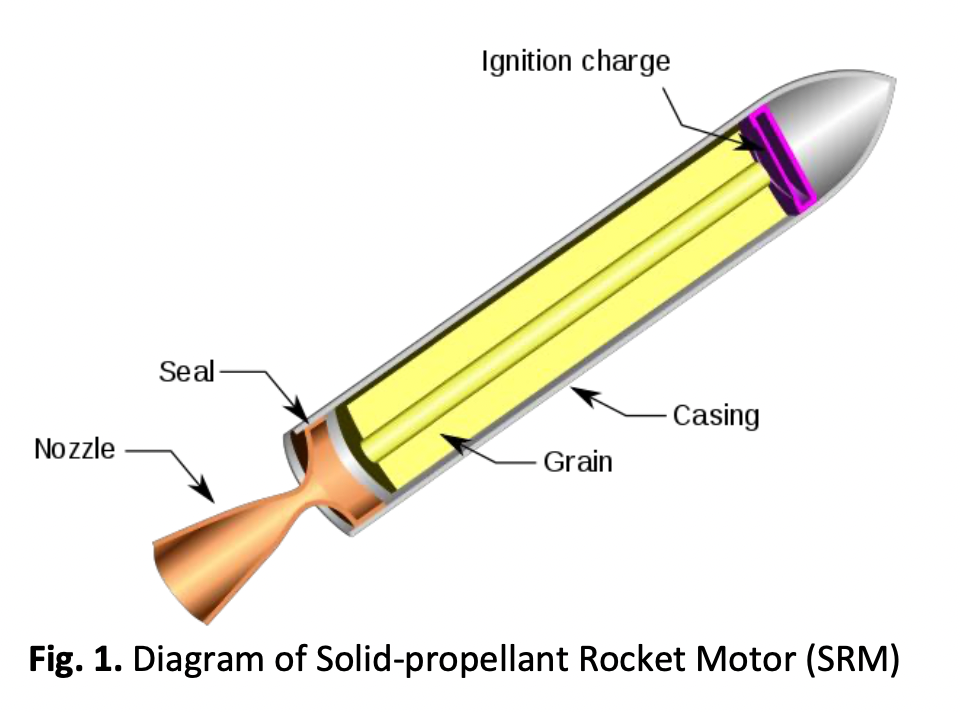

The development of rockets in Indonesia has long been carried out by the National Aeronautics and Space Agency (LAPAN), which has now been integrated into the National Research and Innovation Agency (BRIN). The Research Centre for Rocket Technology, which is one of the centres within BRIN, has been developing solid propellant-based rockets with a various sizes and types. Solid-propellant rocket technology is commonly used because of their reliability, cost-effectiveness, and simple design. However, this technology is one of the high-risk technologies, whose failure can harm humans, damage the environment and cause huge losses to assets. As a high-risk technology, risk assessment activities must be carried out, starting from the design, manufacturing, testing and up to the launching stage. In this paper, we studied a risk assessment for general Solid-propellant Rocket Motor (SRM). SRM is basically a device that processes chemical energy in solid propellant into thrust (kinetic energy) in a container that functions as a pressure vessel. The risk assessment methods commonly used in this technology are the HAZOP or FMEA methods. The HAZOP is excellent in identifying failure modes systematically through identifying the deviation of physical process parameters but has difficulties in prioritizing the risk. The FMEA has effectiveness in understanding failure mechanisms and establishing necessary countermeasures, but for a product with a lot of components, the worksheet is also complex. By combining these two methods, integrating the superiority of each method, this research can identify modes, causes and effects of failure that may occur in SRM effective and accurately. In addition, this research also proposes corrective or preventive actions for each failure mode. As the objective of the risk assessment, results of the research can be used as input for the designers to improve their design and as inspection and surveillance objects for QC officers.

Downloads