Production of Hydrogen from Rice Straw through Enzymatic Hydrolysis by Optimally Prepared Crude Cellulase Mixture Followed by Fermentation and Its Hydrodynamic Study

DOI:

https://doi.org/10.37934/arfmts.112.1.189203Keywords:

Hydrogen, rice straw, optimal crude cellulase mixture, hydrodynamic studyAbstract

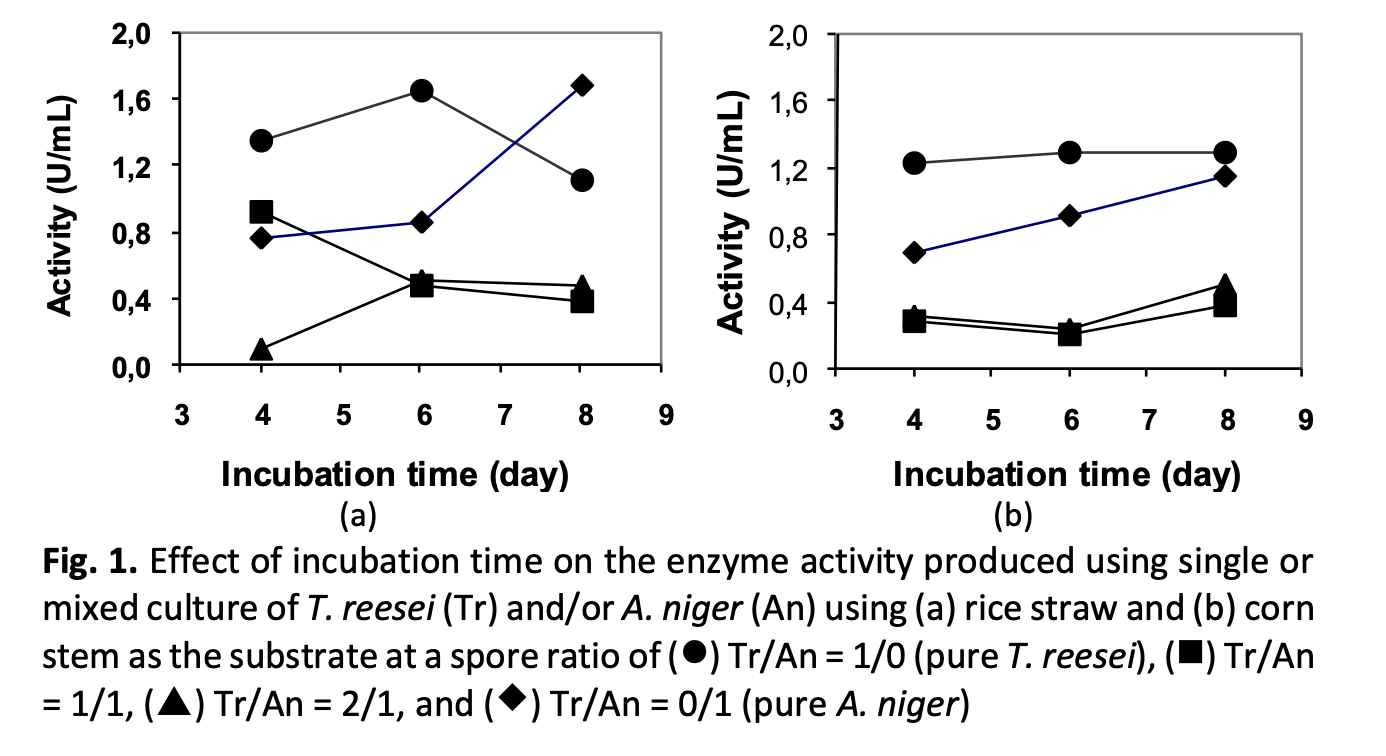

Production of hydrogen from rice straw was conducted through alkaline pretreatment, enzymatic hydrolysis, and fermentation. The hydrodynamic study was performed to investigate the effect of mixing to hydrogen gas produced during the heterogenous mixture in the fermentation tank. 2 % NaOH was found effective in reducing the lignin content in rice straw as evidenced from quantitative data and confirmed by the SEM image. Based on the optimum values of pH and temperature as well as the stability of enzyme, the hydrolysis was performed at pH 5.5 and 40 oC. The mixture of crude cellulases was able to give higher conversion than cellulase from one source of fungi and also higher than the conversion using pure commercial cellulase from Aspergilus niger. A unit activity ratio of 1 U A. niger cellulase to 2 U Trichoderma reesei cellulase was able to increase the reducing sugar concentration by 16%. Hydrogen fermentation was affected by the stirring speed in which increasing the stirring speed from 46 to 165 rpm increased the hydrogen recovery from 0.025 to 0.085 mol H2/mol glucose. Simulations showed that the intensity of turbulence was greatest in the impeller area. By increasing rotational speed, the intensity of turbulence in all parts of the reactor will be more evenly distributed which can increase the diffusion of the substrate to the cell surface and increase the rate of biogas leaving out the solution. Furthermore, by increasing the stirring speed, the volume fraction of biogas at the bottom of the reactor is getting smaller which indicates more gas has risen to the surface and left the reactor. The study was the first report to study the hydrodynamic of hydrogen production from lignocellulose during the heterogenous fermentation mixture.

Downloads