Numerical Modeling and Geometry Enhancement of a Reactive Silencer

DOI:

https://doi.org/10.37934/arfmts.106.1.147157Keywords:

Muffler, CFD , acoustic model, reactive silencerAbstract

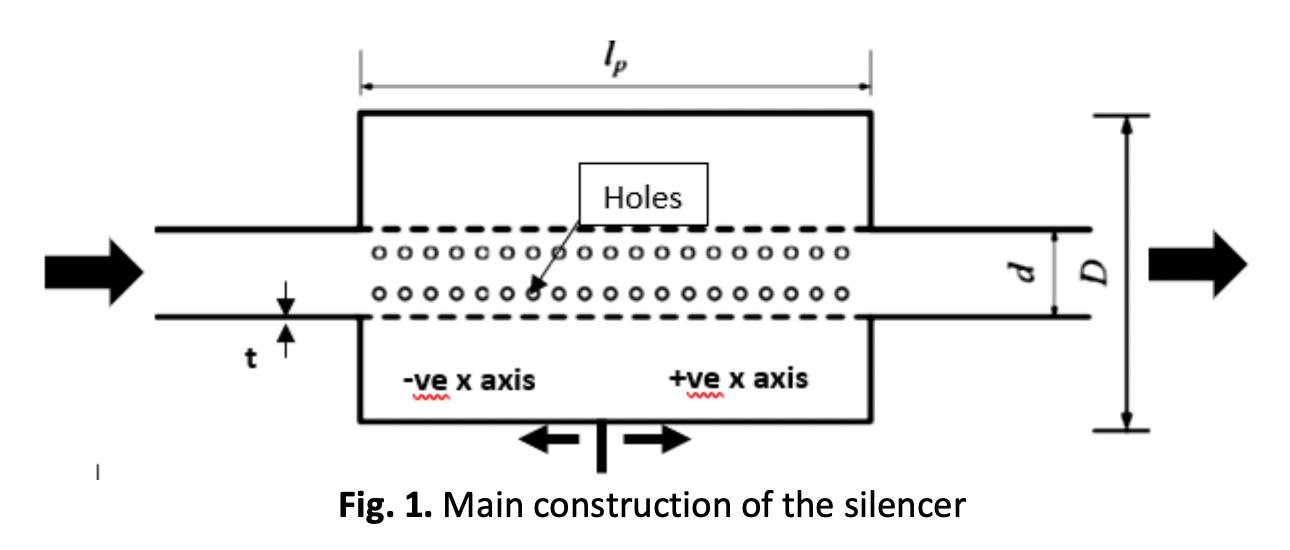

Internal combustion engines and blowers frequently utilize silencers to reduce exhaust noise. In the current paper, the transmission loss of reactive silencers is predicted using the plane wave decomposition method and a three-dimensional (3-D) time-domain computational fluid dynamics (CFD) approach. A mass-flow-inlet boundary condition is first used to perform a steady flow computation, which serves as an initial condition for the two subsequent unsteady flow computations. At the model's inlet, an impulse (acoustic excitation) is placed over the constant mass flow to perform the first unstable flow computation. Once the impulse has fully propagated into the silencer, the non-reflecting boundary condition (NRBC) is then added. For the scenario without acoustic excitation at the inlet, a second unsteady flow computation is performed. During the two transient computations, the time histories of the pressure and velocity at the upstream measuring points as well as the history of the pressures at the downstream measuring point are recorded. The related acoustic quantities show variations between the two unsteady flow computational findings. As a result, the transmitted sound pressure signal is just the sound pressure downstream, while the incident sound pressure signal is obtained by utilizing plane wave decomposition upstream. The transmission loss (TL) of the silencer is then calculated after the Fast Fourier Transform (FFT) converts the two sound pressure signals from the time domain to the frequency domain. The numerical calculations and the reported data are in good agreement for the published results, in addition to geometry enhancement by increasing number of holes in the cross section for muffler.

Downloads