Effect of KOH Concentration on the Performance of HHO Generator at Varying Plate Surface Textures

DOI:

https://doi.org/10.37934/arfmts.106.2.116128Keywords:

Hydrogen, electrolysis, surface texture, KOHAbstract

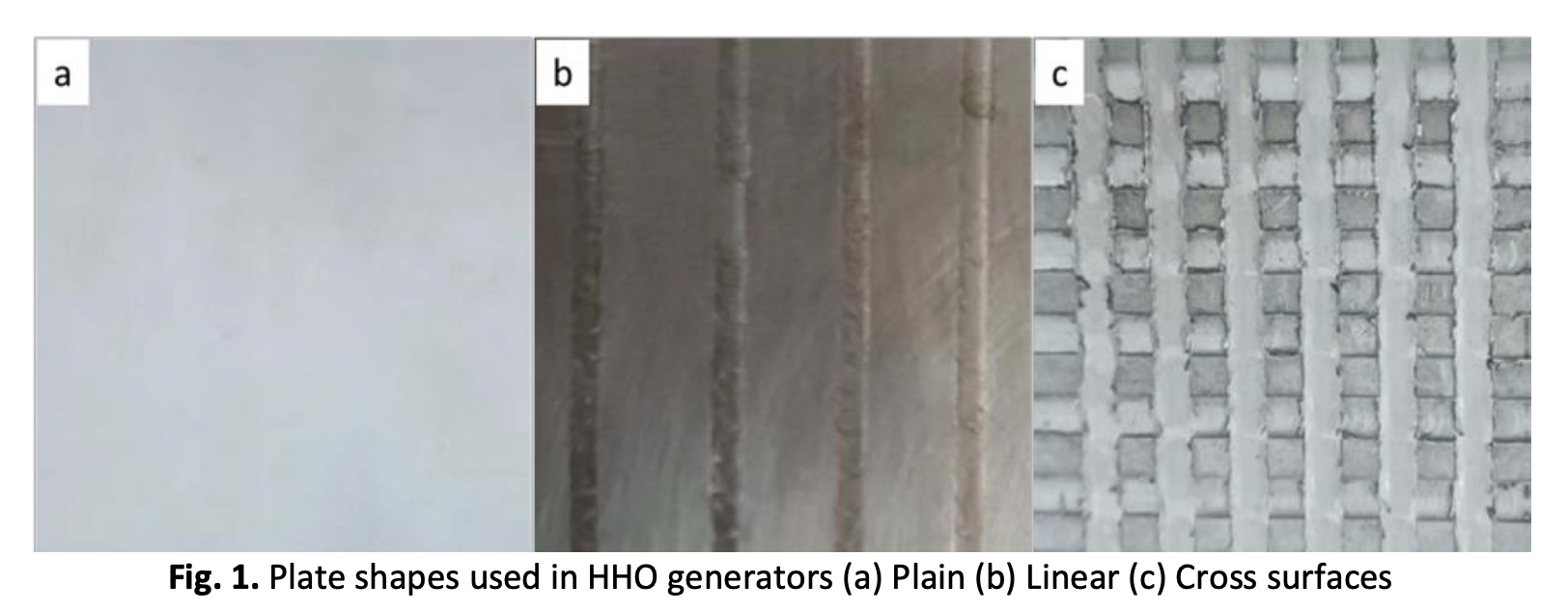

In an effort to improve the performance of the HHO generator, the surface texture of the electrode plate has been introduced through this study. Optimization of the HHO generator’s performance has been developed continuously in many parts of the world. Therefore, the effect of KOH concentration on the performance of the HHO generator at different plate surface textures was investigated in this study. The HHO generator used in this study combines wet and dry cells. Generally, the results showed an increase in output current, HHO production rate, and output temperature, and conversely, a decrease in operating time due to the effect of increasing KOH concentration and different surface textures. The output current exhibits a significant increase of over 200% for all types of plate surfaces. For the output temperature, the smallest increase of about 9.7% is achieved by the linear plate surface. Meanwhile, the best HHO gas production rate is 267.26 L/min with an operating time of only 112.25 s, which occurred on the surface of the linear plate. Briefly, increasing the KOH concentration followed by modification of the plate surface has yielded better results compared to the plain surface. As for the surface texture, it causes a change in the plate surface area, which has a positive impact on the performance of the HHO generator.

Downloads