Study on The Improvement of Heat Recovery Steam Generator Efficiency – A Review

DOI:

https://doi.org/10.37934/arfmts.94.2.8998Keywords:

Steam boiler, cogeneration, HRSG, CFDAbstract

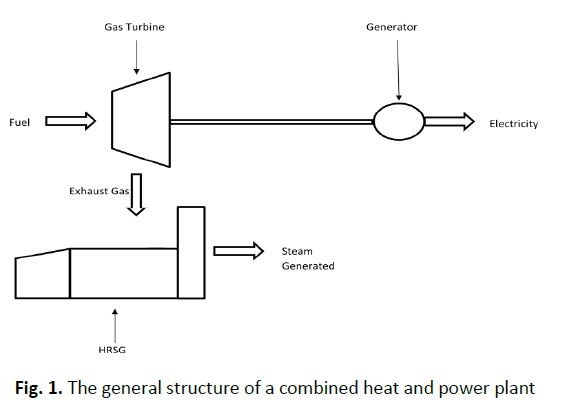

Boilers are widely used in industries to produce steam. In some sectors, the steam generated is utilized directly in the production line for heating. Certain industries use steam to produce electricity. Fire tube boilers are limited to generating steam for processing; meanwhile, water tube boilers are widely used in electricity generation besides steam generation for processing lines. Subcritical boilers, supercritical boilers, and Heat Recovery Steam Generator (HRSG) are types of boilers commonly used to produce high capacity steam. This review article focuses on the optimization of HRSG operational efficiency. Industry players are keen on the improvement of operational efficiency since these directly influence the operating cost. Steam pressure, steam output, heat transfer efficiency and temperature distributions are key areas comprehensively reviewed in this article. Generally, improvement studies on boilers are not feasible to conduct during operation. Therefore, the scaled-down model used in the experiment or the boilers CFD models are simulated to understand the characteristics of the boilers. This review article is expected to overview HRSG boiler efficiency improvements and factors influencing boiler operational parameters.

Downloads