Al2O3 and SiO2 Nanofluids Performance in Thermoelectric Generator

DOI:

https://doi.org/10.37934/arfmts.107.1.4557Keywords:

Heat transfer, hybrid nanofluids, power generation, TEGAbstract

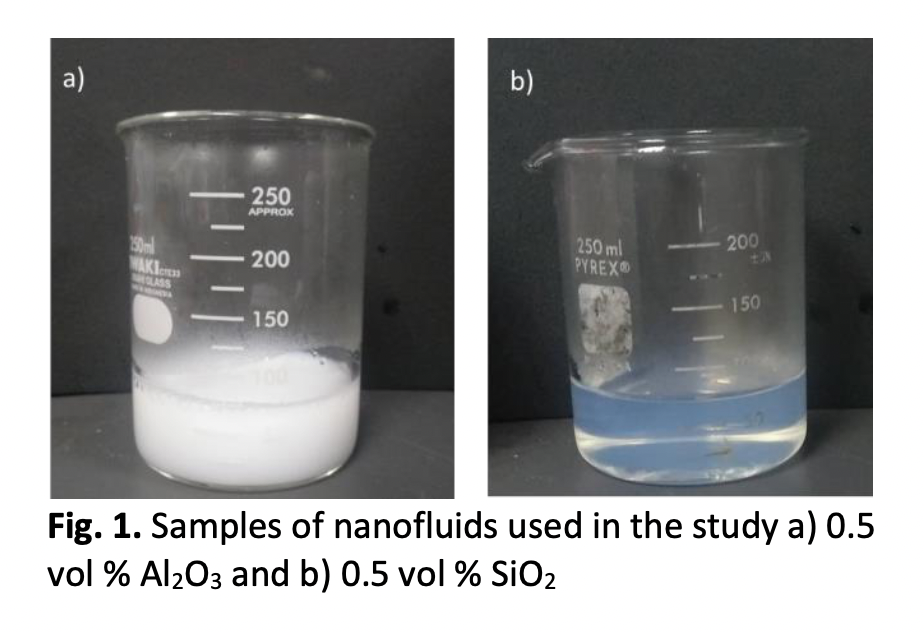

Thermoelectric generator, TEG, is a device that converts heat into electricity through the Seebeck effect. Nanofluids on the other hand are a fluid that contains suspension of nanoparticles in a base fluid. Nanofluids provide better heat transfer performance as compared to conventional coolants which is attributed to the presence of nanoparticle suspension in the base fluid. The purpose of this study is to observe the performance of a single TEG when subjected to nanofluids as the cooling medium. In this study, single Al2O3 and SiO2 nanofluids at 0.5% volume concentration were used and circulated at different flowrates. The performance of TEG was then observed through the power output of TEG. The TEG used was the bismuth telluride, Bi2Te3, where temperature of 80°C is applied to the hot side of the TEG. Simultaneously, nanofluids were circulated at the cold side of the TEG with flowrates of 12, 49, 80 and 112 mL/s. The effect on the temperature difference in the TEG, thus producing different voltage was observed. Power is then calculated from the obtained voltage and current. SiO2 nanofluids was able to increase the maximum power output by 45%, while Al2O3 nanofluids increased the maximum power output by 70%.

Downloads