Aspen Plus Simulation Analysis on Palm Oil Mill Effluent (POME) Recycling System into Bioethanol

DOI:

https://doi.org/10.37934/arfmts.109.1.4150Keywords:

POME, palm oil, bioethanol, simulation, environmentAbstract

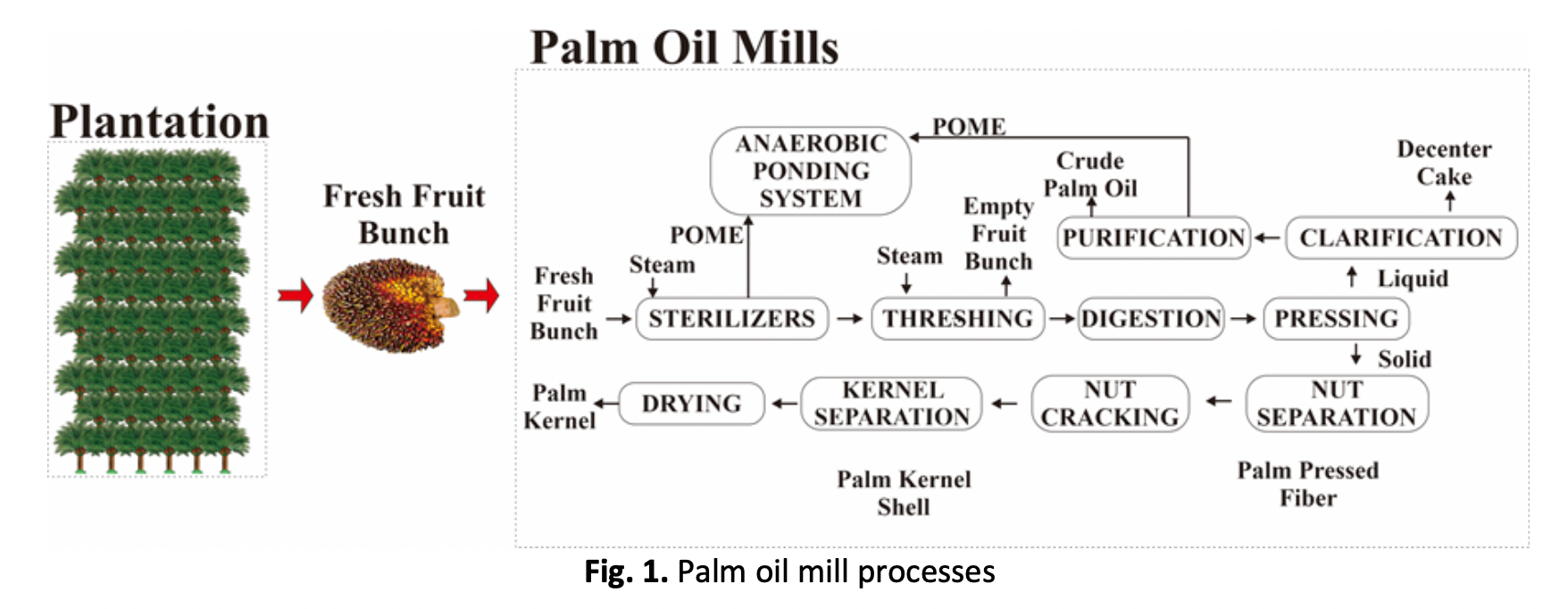

Indonesia is one of the largest exporting countries for palm oil production globally. In 2018, the country had a plantation area of 14.3 Million Ha, with palm Oil Production (Crude Palm Oil) of 40.5 million tons. It generates large amounts of waste, such as Palm Oil Mill Effluent (POME), empty fluid bunch (EFB), fiber, and shells. POME has an organic content and contains carbohydrates, lipids, and proteins. Generally, the POME by-products from palm oil mills in North Sumatra Province are processed using an Anaerobic treatment before environmental release. This method still disposes of pond waste. It produces CH4 and bad smells in the environment. This research uses Aspen Plus software to analyze converting the POME into bioethanol renewable energy that reduces environmental pollution caused by POME. Bioethanol production is processed biologically by fermentation. Based on the analysis of simulation, 10 L tons/day POME can produce main products 0.187 L Ton/day bioethanol with the content of up to 41.95% C2H5OH, 9.29% H2O, and 48.76% CO2, and by-products of 9.823 L Ton/day with the content of 99.7% H2O.

Downloads