Forced Air Cooling for Battery Module on Series Connected Batteries: Temperature Variation Due to Non-Uniform Flow Across Channel

DOI:

https://doi.org/10.37934/arfmts.111.1.226236Keywords:

Lihtium-ion battery, heat transfer, CFDAbstract

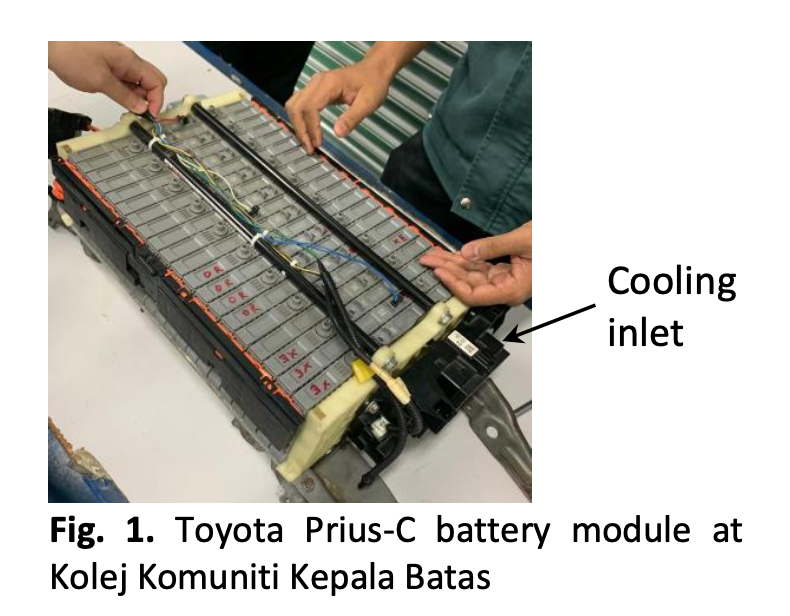

Cells in battery pack for electric vehicle are typically connected in series to meet system voltage requirement. In series connection, each cell will experience identical amount of current drawn, therefore the amount of heat generation for each cell will be relatively similar. Nevertheless, this depends on the cell internal resistance which causes joule heating. To mitigate increase in temperature in the pack, cooling system is necessary. Forced air cooling is the most straightforward cooling system as it pulls cool air from inside the vehicle cabin, and the air will be channeled through cooling routes in the battery module. Typically, the cell located close to the inlet of the cooling system gets the maximum cooling rate, and the cooling capacity reduces as air passes towards the last cell in the module. Two cooling designs are explored in which air velocity is varied by changing the cross-sectional area of inlet air whilst keeping the same mass flow rate. This causes the inlet air velocity to change, to which the airspeed for a small air inlet will be higher than a larger inlet. It shows that higher air speed promotes better cooling only at the first and last cell in the module with a temperature gradient up to 15°C. A battery module with a higher cross-sectional area provides a more uniform heat transfer rate whereby the individual cell temperature is relatively similar with 50% more consistent than the smaller cross-sectional area. This demonstrates that having a higher air speed is not the key attribute in determining the cooling factor of a battery module/pack.

Downloads