Investigation of the Thermal Performance of a Nanofluid-filled Grooved Cylindrical Heat Pipe for Electronics Cooling

DOI:

https://doi.org/10.37934/arfmts.99.2.135154Keywords:

Capillary grooves, electronics cooling, heat pipe, nanofluids, modelingAbstract

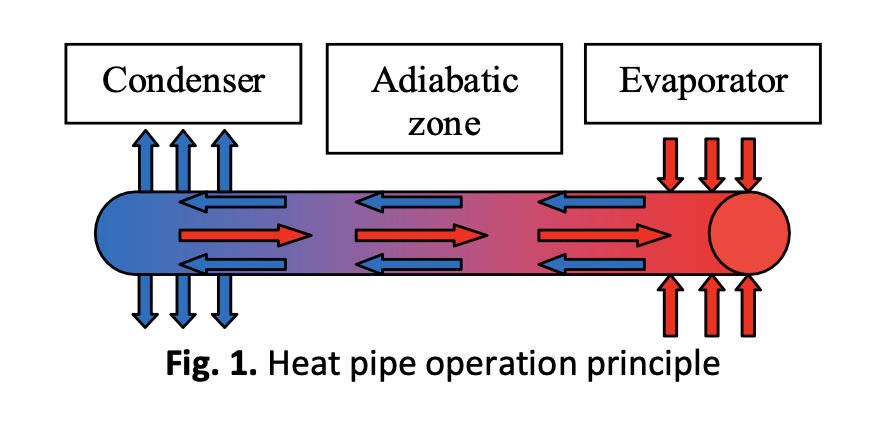

Thermal management of electric and electronic components is a critical issue and needs to consider enhanced cooling systems such as heat pipes. This study deals with the theoretical modeling of a nanofluid-filled copper cylindrical heat pipe for electronics cooling applications. The heat pipe includes helicoidal and trapezoidal capillary grooves. The model can predict the capillary limit as well as the heat transfer in the different sections of the heat pipe. The thermal resistances of the evaporation and condensation sections are calculated based on correlations for heat transfer, which are determined from experiments. Two working nanofluids are considered: water/CuO and water/Al2O3. The thermal performances are predicted for different concentrations and heat sink temperatures, and the heat pipe is positioned horizontally. For both nanofluids, the results indicate that augmenting the concentration of the nanoparticles leads to a capillary limit increase reaching up to 14 % and 25 % for water/Al2O3 and water/CuO, respectively, and an overall thermal resistance decrease reaching up to 51 % and 68 % for water/Al2O3 and water/CuO. Moreover, decreases up to 24 %, and up to 18 % in the evaporator wall temperatures are obtained for water/CuO and water/Al2O3 nanofluids, respectively. The nanofluid water/CuO gives the best thermal performance whatever the nanoparticle concentration and heat sink temperature.

Downloads