Study of Honeycomb Air Curtain for a Freezer Room to Enhance Protection against Warm Air Infiltration

DOI:

https://doi.org/10.37934/arfmts.94.2.123141Keywords:

CFD, FCU, freezer room, air curtain, common grille, honeycomb grilleAbstract

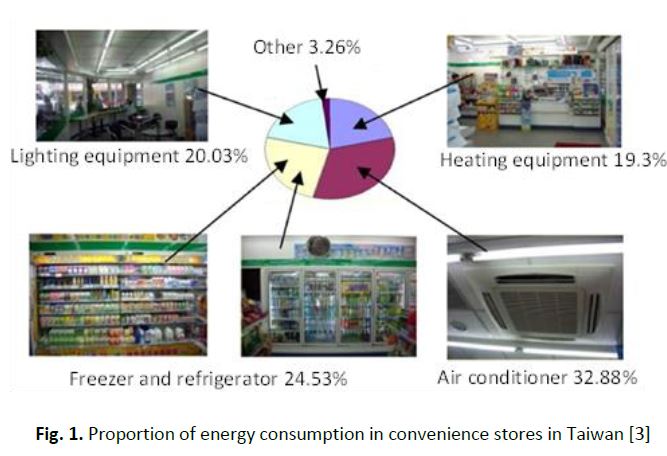

The objective of this research is to present the energy-saving effect of applying an air curtain to prevent the penetration of warm air through a freezer door. Retail business is highly competitive in many aspects, including the factors affecting the cost of the store. The most important cost for many businesses is the cost of supplying energy to refrigeration systems. Therefore, the operator must try to reduce the energy consumption of the freezer room. Normally, a freezer room consumes cooling energy when its door is opened for the loading and unloading of goods, leading to the infiltration of warm air from outside. For this reason, we conducted experiments in which air curtains were used. We compared two types of air curtain grille: Common and honeycomb. The experiment was designed to assess whether the honeycomb grille could provide a stronger air curtain and more effectively prevent the penetration of warm air. For the experiment, we used a freezer with a temperature of −25 ๐C. The freezer room door measured 200 × 100 m2 and an air curtain was installed 5 cm above the outer freezer door. The velocity of the air curtain was 6.5 m/s. Simulations were carried out using solid workflow simulation software. The changes in temperature and air velocity were simulated in the room, considering three scenarios: Type 1: Leaving the freezer door open for 1 hour without the air curtain operating. This resulted in warm air inflow at the top of the door and cold air outflow at the bottom of the door. When a steady-state was reached, the room temperature was 6.05 ๐C. Type 2: Leaving the freezer door open for 1 hour, using an air curtain with a common grille to prevent the infiltration of warm air. The results showed that an air curtain could prevent the infiltration of warm air. The outside air tries to push through the air curtain, which can be seen from the curvature of the air curtain line in the model. When a steady-state was reached, the room temperature was −2.41 ๐C. Type 3: Leaving the freezer door open for 1 hour, using an air curtain with a honeycomb grille to prevent the infiltration of warm air. The honeycomb grille air curtain was slightly better at preventing the infiltration of warm air than the common grille. There was less curvature in the air curtain line, which means that the strength of the air curtain is greater. When a steady-state was reached, the room temperature was −2.64 ๐C. In conclusion, the results demonstrated that the honeycomb grille air curtain can prevent the infiltration of warm air 9.54% better than the common grille air curtain.

Downloads