Experimental Determination of Transport Parameters of Dragon Fruit Slices by Infrared Drying

DOI:

https://doi.org/10.37934/arfmts.97.2.8090Keywords:

Fruit drying, drying condition, post-harvest technology, agricultural preservationAbstract

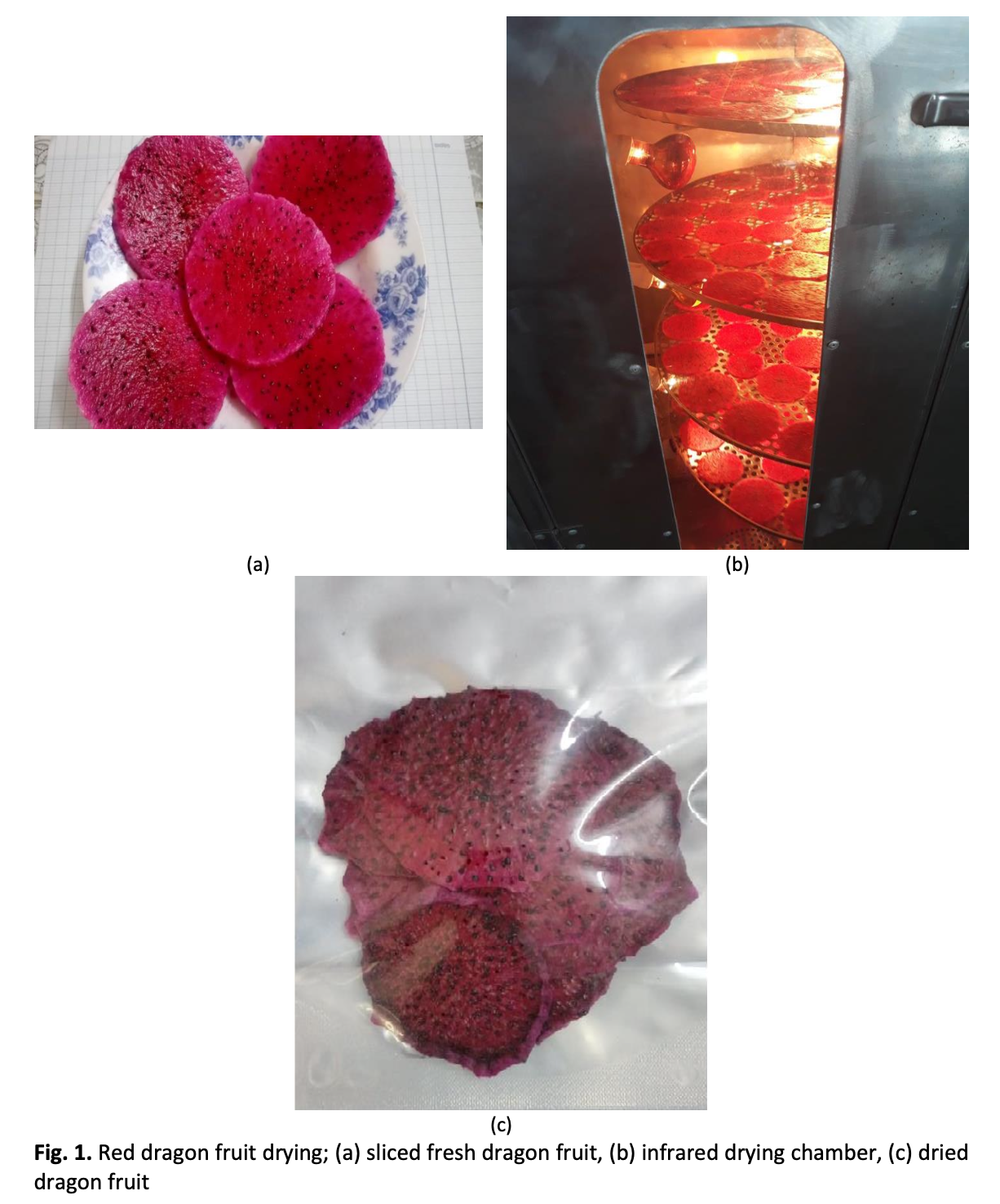

Infrared drying is an advanced drying method that preserves the nutritional value of the dried object. Currently, dragon fruit drying on a static tray by hot air circulation reveals disadvantages of long drying time and ununiform moisture distribution. In this study, Vietnam red dragon fruit was dehumidified in a vertical cylindrical infrared dryer. The drying mode includes radiation intensity in the range of 4 to 6 kW/m2 and air velocity in the range of 1 to 3 m/s to investigate moisture transfer parameters and vitamin content in dragon fruit. The drying time was fixed at 10 hours to evaluate the final moisture content and vitamin contents. Henderson and Pabis drying model was adopted with the coefficient of determination greater than 0.98. Results show that the moisture diffusivity in the infrared drying was achieved in the range of 2.3e-9 to 3.9e-9 m2/s. Moisture transfer coefficient of the dragon fruit varied in the range of 4e-5 to 1.2e-4 m/s. The Biot number in the drying by an infrared lamp ranged from 40 to 80. Vitamin C in dried dragon fruit has a high content of up to 13.5 mg/100 g. The current dragon fruit drying by infrared lamp reveals negligible surface resistance to mass transfer. The infrared drying of dragon fruit is a feasible alternative to preservation. Also, seeking of an optimal tray rotation speed may be further improvement of the drying rate.

Downloads