Optimization of Biodiesel Production from Beef Tallow Using Microwave Assisted

DOI:

https://doi.org/10.37934/arfmts.97.2.5765Keywords:

Biodiesel, Beef Tallow, Response Surface MethodologyAbstract

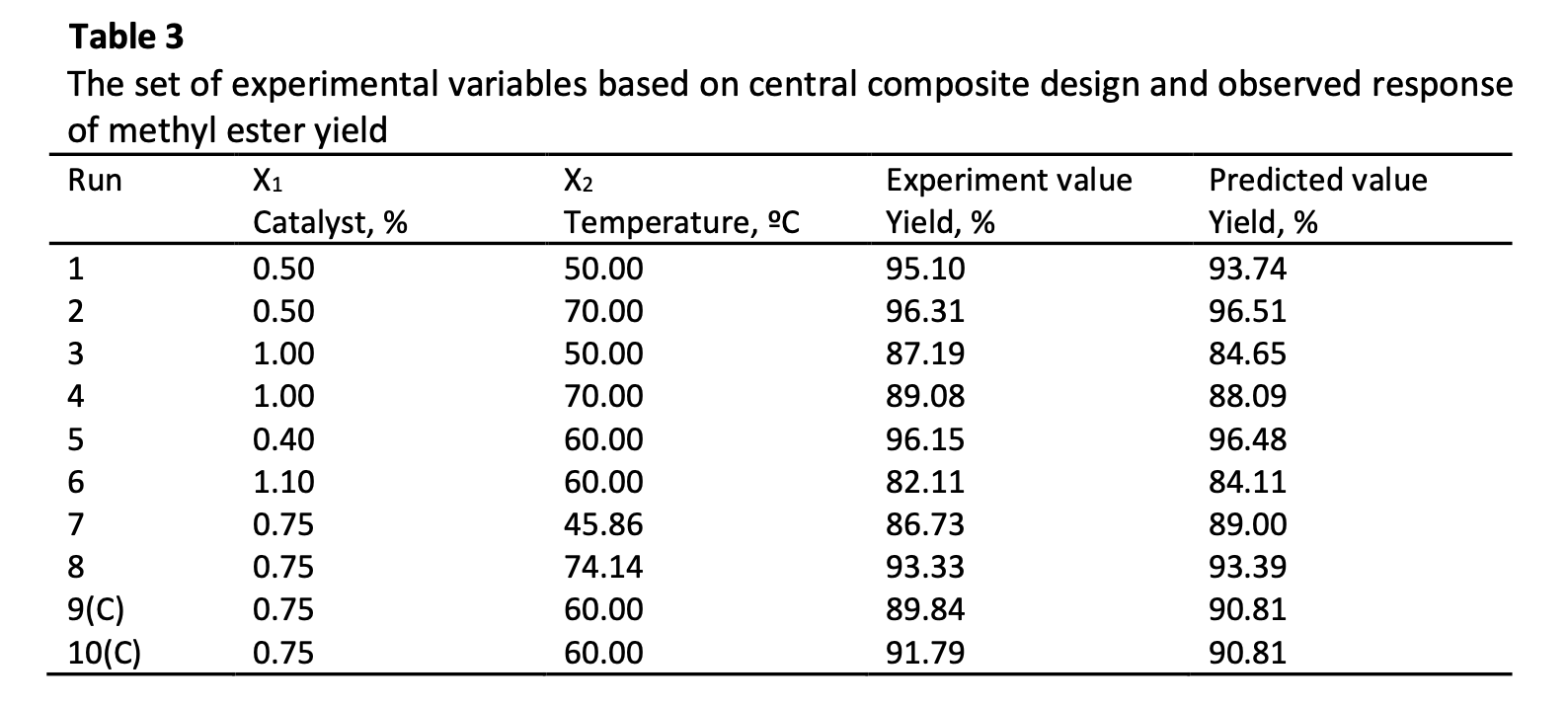

The need for fuel in Indonesia is increasing every year. Renewable and environmentally friendly alternative fuels are the right choice to meet national energy need and can substitute fossil fuels. Biodiesel has been widely applied in diesel engines that run on diesel fuel. Biodiesel is processed from plant and animal oils or fats. Non-edible oil is preferable to be processed into biodiesel because it doesn’t interfere with food availability. Beef tallow has abundant availability, the users are still few, and has an ALB content of <1%, making it suitable as a raw material for biodiesel. The transesterification reaction to process oil (triglycerides) into biodiesel (methyl ester) requires effective heating, one of which is the microwave method. Optimal process conditions are required to produce high biodiesel yields. Therefore, the data optimization process is carried out in order to obtain the optimum conditions and save the number of running. In this study using the reaction temperature and catalyst concentration (%weight) as independent variable. The fixed variables and were the mole ratio of methanol: oil (6:1), reaction time (20 minutes), power (200 watt) and stirring speed (200 rpm). Data analysis of optimization used the Response Surface Methodology (RSM) based on Central Composite Design (CCD) with the help of the software STASTICA 10. The research results the optimum yield was 98.736% at conditions of reaction temperature 74.142ºC and catalyst 0.396%weight. Mathematical equation for optimum conditions y = 90.81073 - 8.74778 X1.

Downloads