Development of the Dethridge Wheel Blade Shape for Hydropower Generation in Irrigation Canals in Indonesia

DOI:

https://doi.org/10.37934/arfmts.98.2.146156Keywords:

Dethridge wheel, waterwheel, wheel blade, hydropower, pico hydro, irrigationAbstract

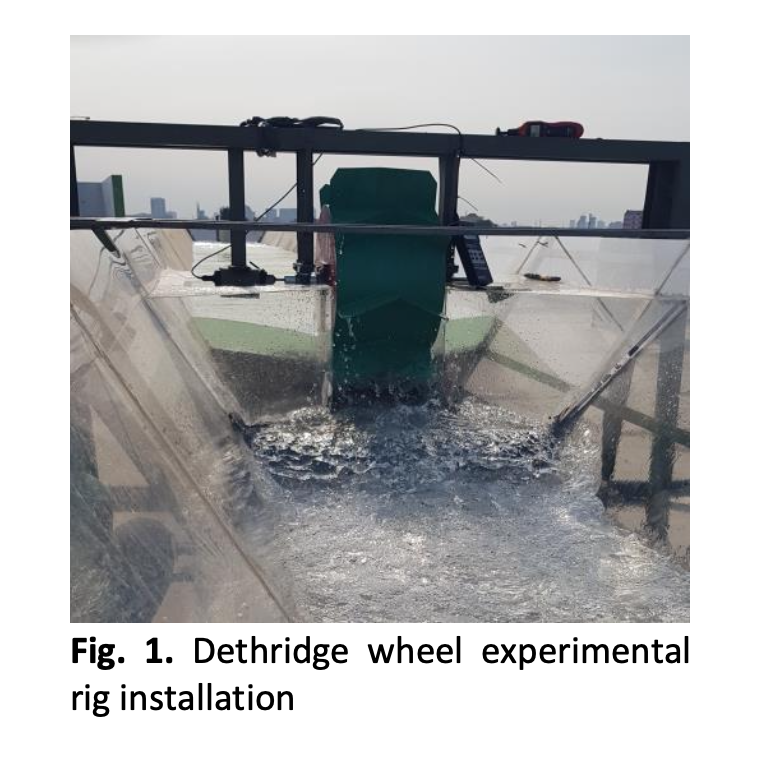

Consumption of electrical energy continues to increase along with population growth. As a result, various sources of electrical energy are utilised to meet these needs, especially in areas that have not been reached by the national electricity network. In countries with hilly geography and irrigation canals, pico hydro energy is often considered an alternative. One of the tools used to convert water flow energy into electrical energy is the Dethridge wheel. The Dethridge wheel is a simple waterwheel that is easy to manufacture and suitable for irrigation canals with very low water head heights. This study aims to increase the performance of the Dethridge wheel by changing the shape of the wheel blades and examine the effect of the variation of water flow rate in the channel. Experimental and numerical methods were used to investigate the potential of the developed wheel. The Dethridge wheel and its development were tested using an artificial irrigation canal with flow rates of 20, 30, 60, 90 and 120 m3/h. Furthermore, a three-dimensional numerical model of the Dethridge wheel was simulated using Ansys Fluent 18.2 software. The highest efficiency of the experimental Dethridge wheel, 55.6%, was achieved when the flow rate was 30 m3/h. The developed Dethridge wheel efficiency increased to 71.72%. These results are also in agreement with the simulated model.

Downloads