Optimization of the Effect of Hydraulic Hot-Pressing-Process Parameters on Tensile Properties of Kapok Fiber Nonwoven Web Based on Taguchi Experimental Design

DOI:

https://doi.org/10.37934/arfmts.115.1.156165Keywords:

Raw kapok fibers, nonwoven, hot-press, tensile test, Taguchi methodAbstract

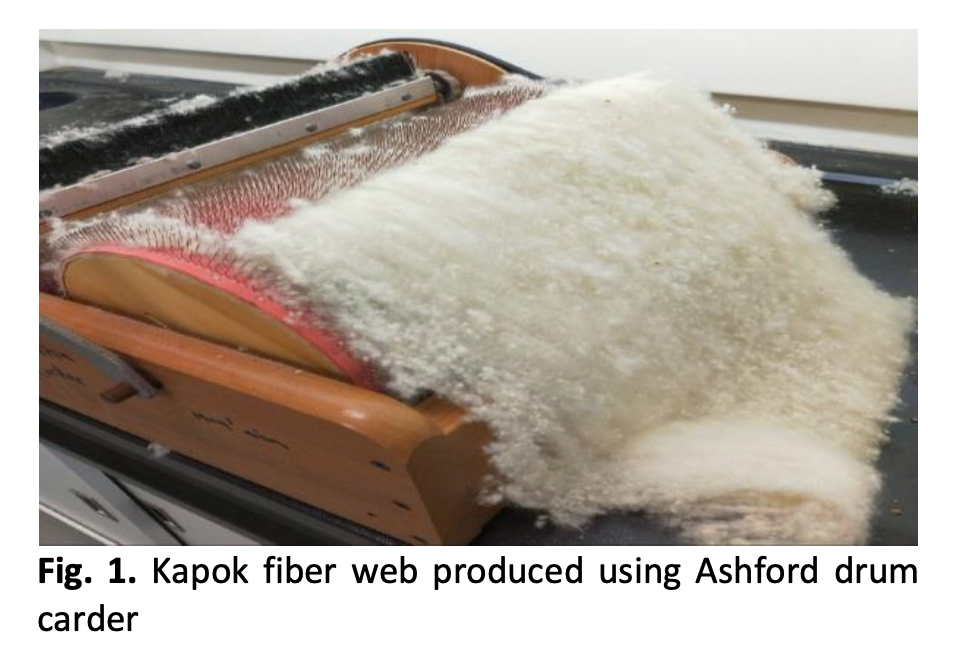

This paper investigates the effect of temperature on the physical properties of Kapok fiber web formed via the hot-pressing method. The kapok web was prepared using the Ashford drum carder. Test samples were subjected to heat treatment in a hydraulic hot-press under three different temperatures (160, 170, and 180°C), heating durations (5, 7.5, and 10 min), and pressures (500, 750, and 1000 psi). This study was conducted to clarify the tensile properties of kapok fabrics under optimal hot-press-forming process parameters such as temperature, heating time, and pressure; here, the Taguchi L27 orthogonal array experimental design was adopted for the optimization. The surface morphologies and tensile properties of kapok fabrics were investigated. The optimum combination of process factors was obtained through signal-to-noise (S/N) ratio analysis. Furthermore, analysis of variance was employed to determine the importance of the process parameter levels. Moreover, regression analysis was adopted to mathematically model the metamorphism of tensile properties with process parameters. A set of confirmation tests was also conducted, and the results verified the presented models. This study results showed that all three processing factors had significant influences on the tensile strength of the carded nonwoven kapok. The combination of hot-pressing parameters to obtain the optimum tensile strength was obtained as follows: 170°C temperature, 1000 psi pressure, and 10 min heating time.

Downloads