Boost Pectin Production using Continuous System of Subcritical Water Extraction

DOI:

https://doi.org/10.37934/arfmts.99.2.168179Keywords:

Soluble pectin, fast extraction process, interaction temperature, continuous system SWE, response surfaceAbstract

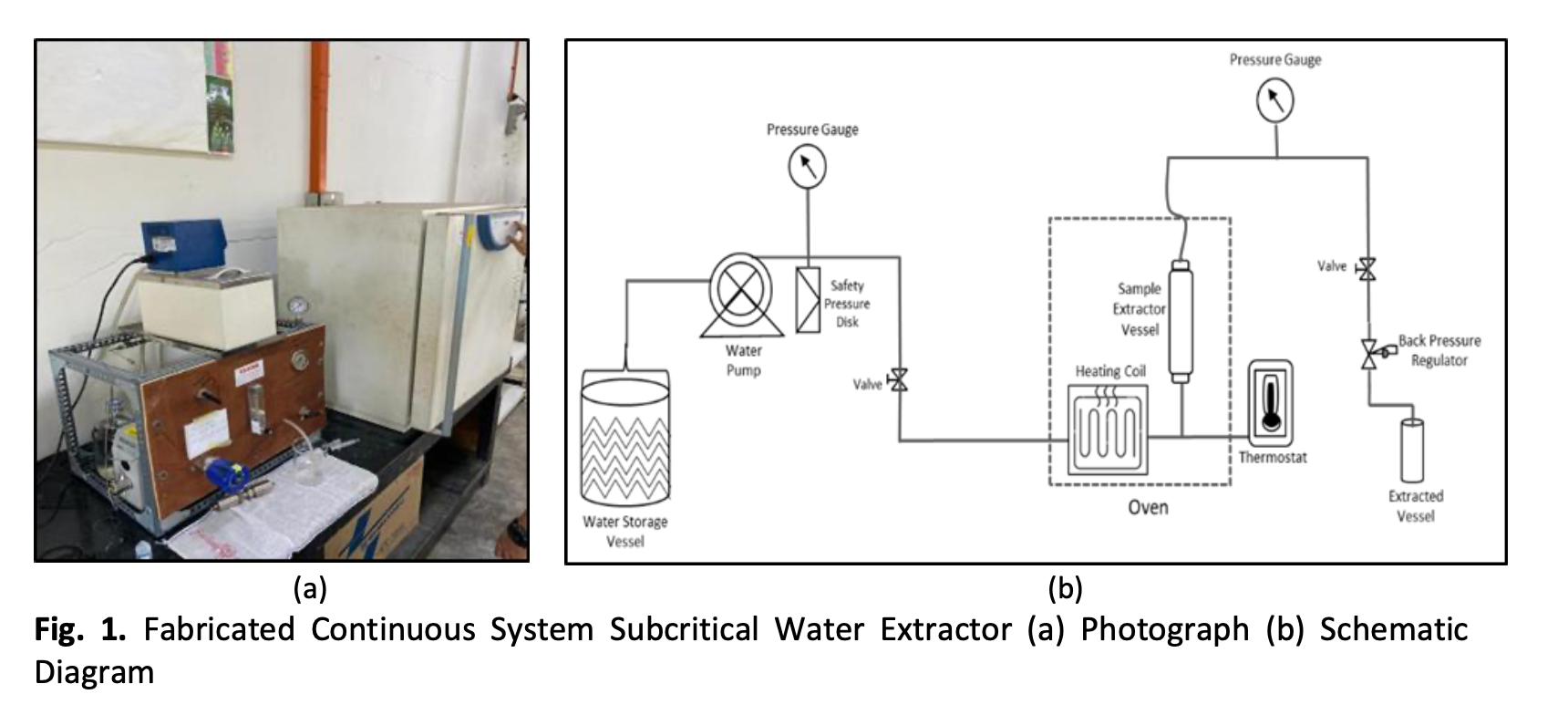

The dumping of waste banana peels from local chip manufacturing has encouraged sustainable food trends to valorize these peels as pectin sources. In this study, soluble pectin from banana peels was extracted using a continuous subcritical water extraction system (SWE). This method was a promising fast extraction process with a water solvent that was environmentally friendly. Temperature (100 to 160 °C) and extraction time (5 to 50 minutes) were manipulated, with a fixed pressure of 15 MPa, a flow rate of 15 mL/min, and a particle size of 0.6 mm. The response surface methodology (RSM) was used to generate approximately 13 experimental trials from the central composite design. Based on linear and square models, the results revealed that the interaction of temperature and time to pectin yield had a significant effect. At 100°C for 5 minutes, an optimal condition for producing pectin yield was achieved, which risen the highest pectin yield by 26%. As a result, the SWE continuous system promoted increased pectin production in the shortest extraction time. In short, banana peel pectin is a powder that serves a primary function in numerous food, pharmaceutical, and cosmeceutical applications.

Downloads