Drying Studies of Oil Palm Decanter Cake for Production of Green Fertilizer

DOI:

https://doi.org/10.37934/arfmts.97.2.6679Keywords:

Drying, oil palm decanter cake, thin layer drying models, moisture ratio, oil palm tree, crude palm oil, palm kernel shell, fresh fruit bunchesAbstract

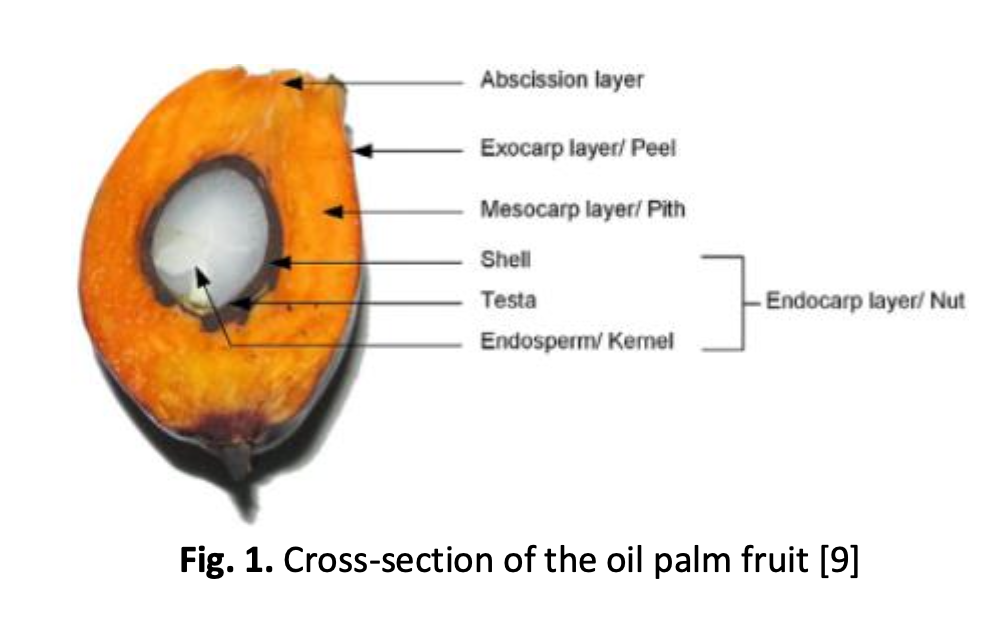

The oil palm tree (Elaeis guineensis) yields palm oil from the flesh of its fruit that can be used in various industries. The extraction process produces decanter cake as one of their waste products. Drying process can be applied to the decanter cake for repurposing. The aim of this study is to determine the drying characteristics of decanter cake from the palm oil mill waste. Four thin layer drying models were used to define the drying characteristics of the decanter cake. The models are Newton model, Henderson and Pabis model, Logarithmic models and Two Term model. The samples were dried at 105°C by using convection oven, following ASTM D2974-20e1 to obtain the moisture content. Non-linear regression by using LAB Fit Curve Fitting Software was used for the statistical analysis to get the predicted data. The predicted data was compared to the experimental data carried out at three different thickness (0.3 cm, 0.5 cm and 1 cm). Coefficient of determination (R2), reduced chi-square (X2) and root mean square error (RMSE) were the statistical parameters involved. Higher R2 with lower X2 and RMSE indicates good correlation and similarities of the model prediction. Results shows that 1 cm is not suitable to be dried within three hours using mechanized dryers. From the analysis, Logarithmic model generated the best predictability for 0.3 cm and 0.5 cm thickness.

Downloads