The Characteristics of Hybrid Al2O3:SiO2 Nanofluids in Cooling Plate of PEMFC

DOI:

https://doi.org/10.37934/arfmts.88.3.96109Keywords:

Hybrid nanofluids, PEMFC, thermal enhancementAbstract

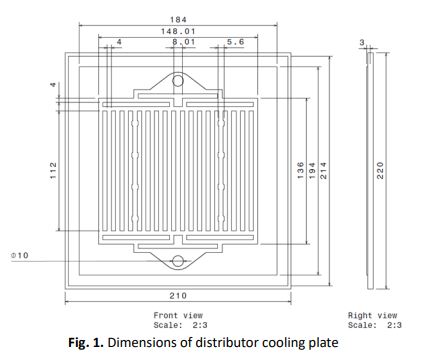

A Proton Electrolyte Membrane fuel cells (PEMFC) is considered to be a viable alternatives to Internal Combustion Engines (ICEs) in automotive applications due to the key advantages in thermal management system. The main duty of thermal management system is to maintain the desirable temperature, with a uniform temperature distribution across the stack and.its.individual membranes. In this paper, the thermal enhancement of a PEMFC cooling plate was analysed and presented. The hybrid Al₂O₃:SiO₂ was used as coolant in distributor cooling plate. The study focuses on water based 0.5% volume concentration of single Al₂O₃ , single SiO₂ nanofluids, hybrid Al₂O₃:SiO nanofluids with mixture ratio of 10:90, 20:80, 50:50, 60:40 and 90:10. The effect of different ratios of nanofluids to heat transfer enhancement and fluid flow in Reynold number range of 400 to 2000 was observed. A 3D computational fluid dynamic (CFD) was developed based on distributor cooling plates using Ansys 16.0. Positive heat transfer enhancement was obtained where the 10:90 Al₂O₃:SiO₂ nanofluids has the highest heat transfer coefficient as compared to other nanofluids used. However, all nanofluids experienced higher pressure drop. Therefore, the advantage ratio was used to analyze the effect of both heat transfer enhancements and pressure drop demerits for nanofluids adoption. The results concluded that 10:90 Al₂O₃:SiO₂ hybrid nanofluid is the most feasible candidate up to fluid flow of Re1000. The positive results implied that hybrid Al₂O₃:SiO₂ nanofluids do improve the single nanofluids behaviour and has a better potential for future applications in PEMFC thermal management.

Downloads