Experimental Study on Effect of Nano ZnO on the Cooling Performance of Motorcycle Radiator

DOI:

https://doi.org/10.37934/arfmts.100.2.169180Keywords:

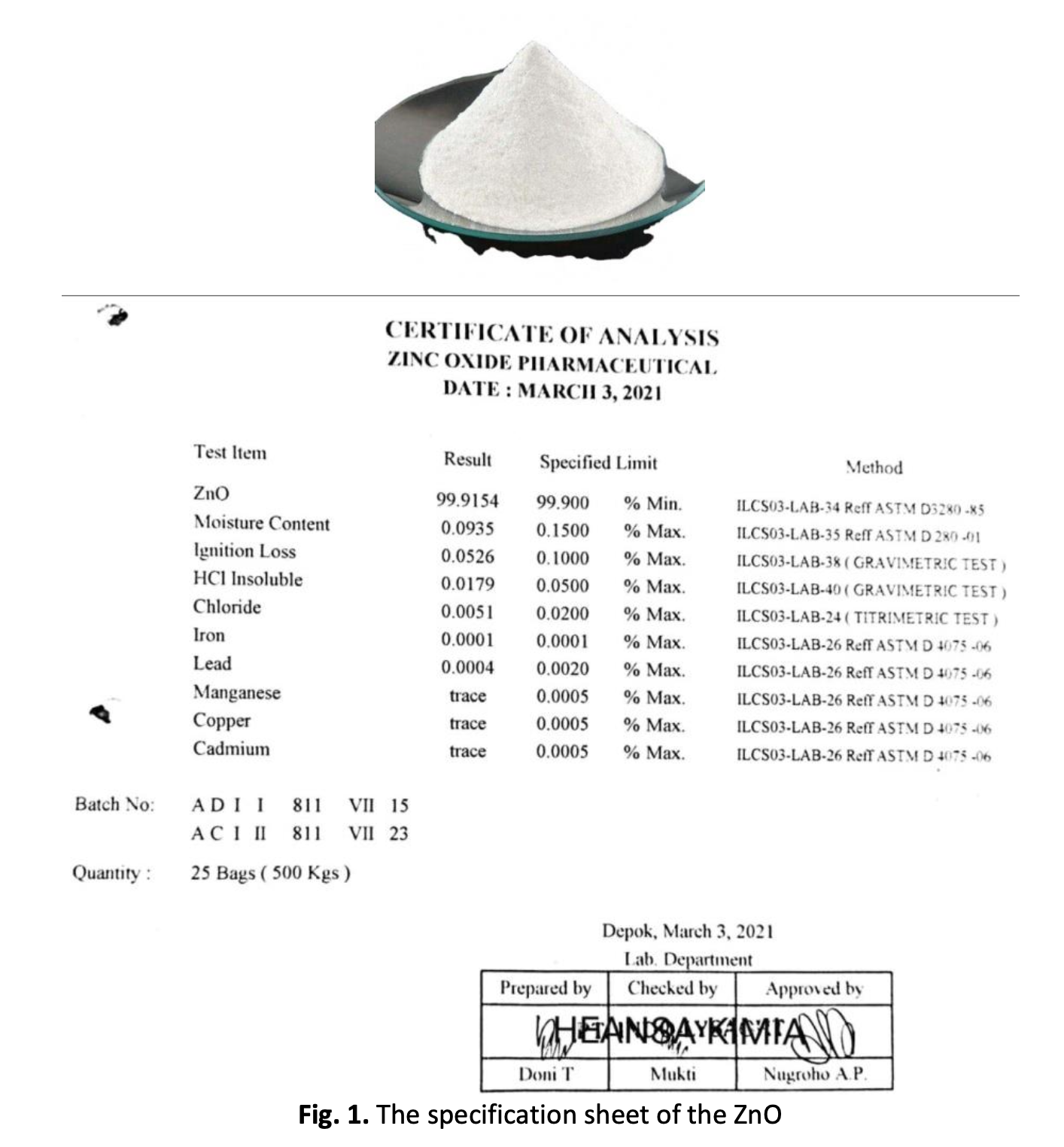

Nanopowder ZnO, radiator, ethylene glycol, overall heat transfer coefficient, pressure dropAbstract

An internal combustion engine requires a proper cooling system to release heat from the engine. The working fluid or coolant in a water-cooled engine impacts the overall radiator cooling performance. Several studies show that nanopowder can increase the thermal performance of the base fluids, although the pressure drops increase significantly. This paper describes the experimental study of motorcycle radiator cooling performance using nanopowder ZnO with distilled water and commercial coolant as the base fluids. The study began by measuring the boiling point and the specific heat of the base fluid (distilled water and commercial coolant) and nanofluids. Then, the flow rate of the cooling fluid was measured as the function of the engine’s rotation speed. The results show that the boiling point of all nanofluids increases with the highest boiling point achieved by 0.5% ZnO – coolant, i.e., 110.06°C. Thus, the nanopowder will keep the cooling fluid in the liquid phase and lower the fluid's specific heat. The fluid with the lowest specific heat is nanofluid 0.5% ZnO – coolant. Low specific heat relates to the higher temperature drops. Nanofluid 0.5% ZnO – coolant has the highest temperature drop. Unfortunately, nanopowder also increases pressure drop by approximately twice the base fluid. Nanofluid 0.5% ZnO – coolant gives the highest overall heat transfer coefficient than other nanofluids or the base fluid, i.e., 42.7 W/m2.°C when its flow rate is 44.2 ml/s.

Downloads