Thermal Energy Storage Characteristics of Paraffin in Solar Water Heating Systems with Flat Plate Collectors

DOI:

https://doi.org/10.37934/arfmts.95.2.113119Keywords:

Paraffin wax, phase change material (PCM), thermal energy storage (TES), solar water heater (SWH)Abstract

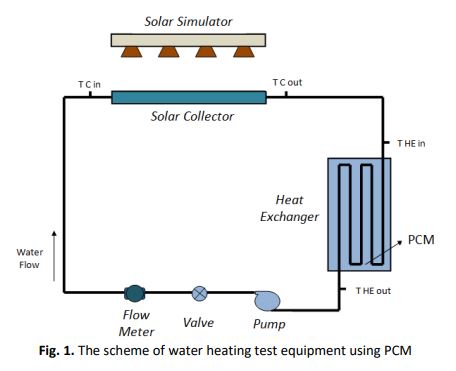

Indonesia is a tropical country with a relatively stable intensity of solar radiation throughout the year, ranging from 10 to 12 hours a day, and averaging 4.8 kWh/m²/day. This great potential can be used for heating water for bathing. Water heating technology based on solar collectors is now widely available in the commercial market. Additionally, thermal energy storage from solar radiation is performed using sensible heat and requires a large volume. Assuming that the water is not used until the afternoon, then the heated water is stored in the tube. A phase change material (PCM) was used in several studies to maximize thermal energy storage (TES) from solar radiation. Also, PCM uses latent heat to absorb and release heat. This is adjusted to the water temperature produced from the solar collector, which attains 70°C. Hence, the potential PCM used is solid paraffin, which is widely available in the market with melting temperatures of 40° to50°C. The study was conducted on a solar water heating system using an 80 cm x 50 cm flat plate collector, and thermal energy storage using paraffin wax. Meanwhile, the heat exchanger used a tube with a diameter of 1 inch arranged in series with a pipe length of 50 cm and 36 rods. The mass of paraffin used was 15 kg or 17.7 liters. Furthermore, the test was performed with variations in the flow rate of water, namely: 2, 3, and 4 lpm, and solar radiation of: 997.5 W/m², 1183 W/m², and 1399.8 W/m². From the results, the thermal energy storage process in PCM paraffin with an amount of 15 kg, took 3.2 hours with a total stored energy of 3.6 MJ. Moreover, solar radiation of 1,399.8 W/m² was used as an energy source and water with a flow rate of 4 lpm as a medium heat transfer. Therefore, this radiation has a very significant effect on the heat transfer process to the PCM, while the flow rate with a value of 2 to 4 lpm does not have.

Downloads