Advanced Pneumatic Control: Real-Time Leakage Detection Using Flow Sensors and Siemens PLC Integration

DOI:

https://doi.org/10.37934/araset.64.2.187198Keywords:

Technology integration, leak detection, PLC program, SDLC modelAbstract

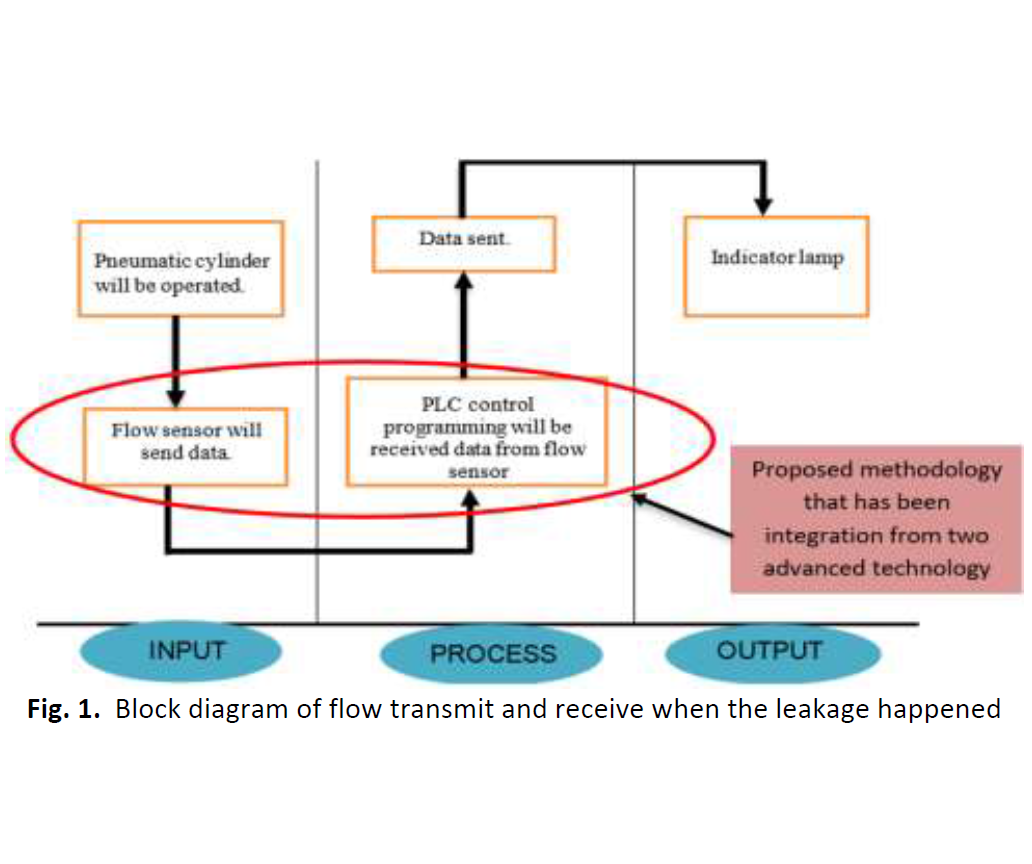

In factory manufacturing, pneumatic cylinder systems play a vital role in various operations. However, they are susceptible to air leaks, which can lead to significant inefficiencies and operational disruptions. This project introduces an innovative solution for real-time air leak detection in pneumatic cylinder systems, leveraging advanced flow sensors and Siemens PLC technology to enhance reliability and efficiency. The primary objective is to develop a sophisticated leak detection system specifically for pneumatic cylinders. The system employs flow sensors to continuously monitor airflow and instantly detect any deviations indicative of a leak. Upon detecting a leak, the system automatically halts the operation of the affected pneumatic cylinders. It activates an indicator light to alert maintenance personnel, consequently preventing further damage and loss of productivity. Key components of this project include the design and assembly of the leak detection hardware, the configuration and analysis of data from the flow sensors, and the development of a robust PLC program using Siemens PLCs to manage and control the leak detection process. Additionally, comprehensive installation guides and instructional videos are provided to facilitate user understanding and implementation. The development of this system follows the Software Development Life Cycle (SDLC) model, encompassing five critical phases: analysis, design, implementation, testing, and evaluation. Each phase was meticulously executed to ensure the system's accuracy and reliability, and extensive testing was conducted to validate the system's performance, confirming its ability to effectively detect and respond to air leaks in pneumatic cylinders. This research not only improves operational efficiency by minimizing air leak-related downtime but also contributes to the sustainability of manufacturing processes by reducing air wastage. Furthermore, the innovative integration of flow sensors and Siemens PLC technology sets a new standard for leak detection in pneumatic cylinder control systems.

Downloads