Effect of Surface Roughness of Pistia Leaves Inspired Surfaces on Oil Contact Angle and Coefficient of Friction under Lubricated Condition

DOI:

https://doi.org/10.37934/araset.35.2.8493Keywords:

Biomimetics, surface roughness, palm oil, contact angleAbstract

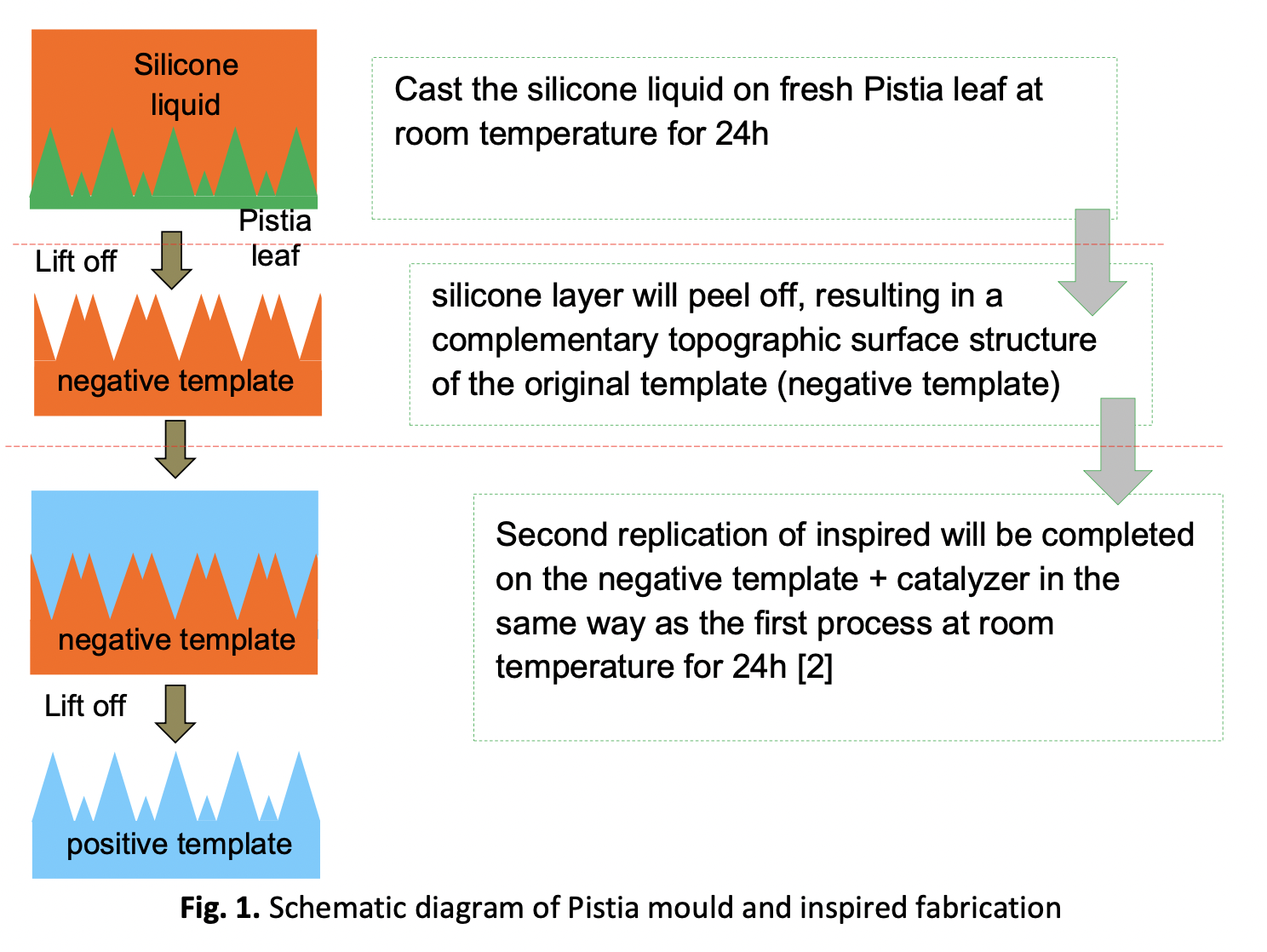

Biomimetics field is getting more interest in engineering purposes. The plant surface roughness existing in nature such as in leaves can be mimicked into artificial technologies. Basically, the surface structures have micro and nano scales in nature and possess properties of interest. Pistia leaves for example have intrinsic of tribology application which have rarely explored. In this study, a preliminary work on 3 types of Pistia leaves inspired surface-based polymer have been conducted to look at effect of surface roughness towards contact angle (CA) measurements and coefficient of friction (COF) under lubricated condition. The surface characteristics were also examined using Variable Pressure Scanning Electron Microscope (VP-SEM). Two different oils namely palm oil and palm oil + TiO2 were tested on the Pistia leaves inspired surface to measure the CA and COF. It was found that both types of palm oils had distinct CA values and COF towards surface roughness of the Pistia inspired surfaces. A maximum difference of CA and COF were recorded in CA and COF values. The different nanocomposite of Pistia leaves inspired surface were found to affect for both parameters CA and COF under lubricated condition.