The Effect of Lignin and Cellulose on Combustion Characteristics of Biocoke

DOI:

https://doi.org/10.37934/araset.52.2.99106Keywords:

Biocoke, Lignin, Cellulose, Combustion characteristics, Thermogravimetric analysisAbstract

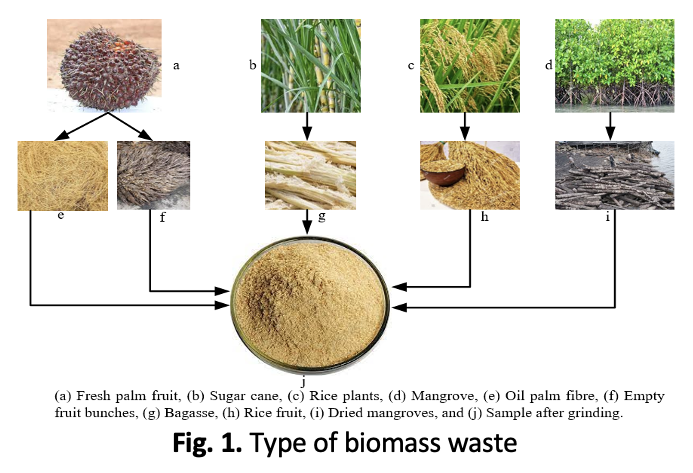

This study investigates the effect of two significant components of biomass, lignin, and cellulose, on the combustion characteristics of biocoke. Lignin, a complex polymer, and cellulose, a polysaccharide, are widely present in biomass and contribute to its structural integrity. The method used to produce biocoke fuel uses a heating and pressing process. Biomass samples include empty fruit bunches, oil palm fibre, rice husks, mangroves, and sugarcane bagasse. The proximate analysis results showed that the highest water content was recorded in palm oil shells. The ash content recorded from rice husks was 15.21% higher than another biomass. The highest energy value was obtained from palm oil shells at 23.53%. Meanwhile, the empty oil palm fruit bunch biomass sample produced the highest lignin content of 59.43%. However, the cellulose content of empty fruit bunches is lower than that of oil palm fibre (37.34% compared to 42.62%). Overall, the heating and pressing methods used for biocoke production can increase the energy content in biocoke. Thus, biocoke fuel has the potential to be an alternative energy source to replace fossil fuels.

Downloads