Experimental and Numerical Investigations of Underground Coal Gasification (UCG) Using Half-teardrop Shape Cavity

DOI:

https://doi.org/10.37934/arfmts.101.2.172183Keywords:

Underground coal gasification (UCG), coal, syngas, gas compositionsAbstract

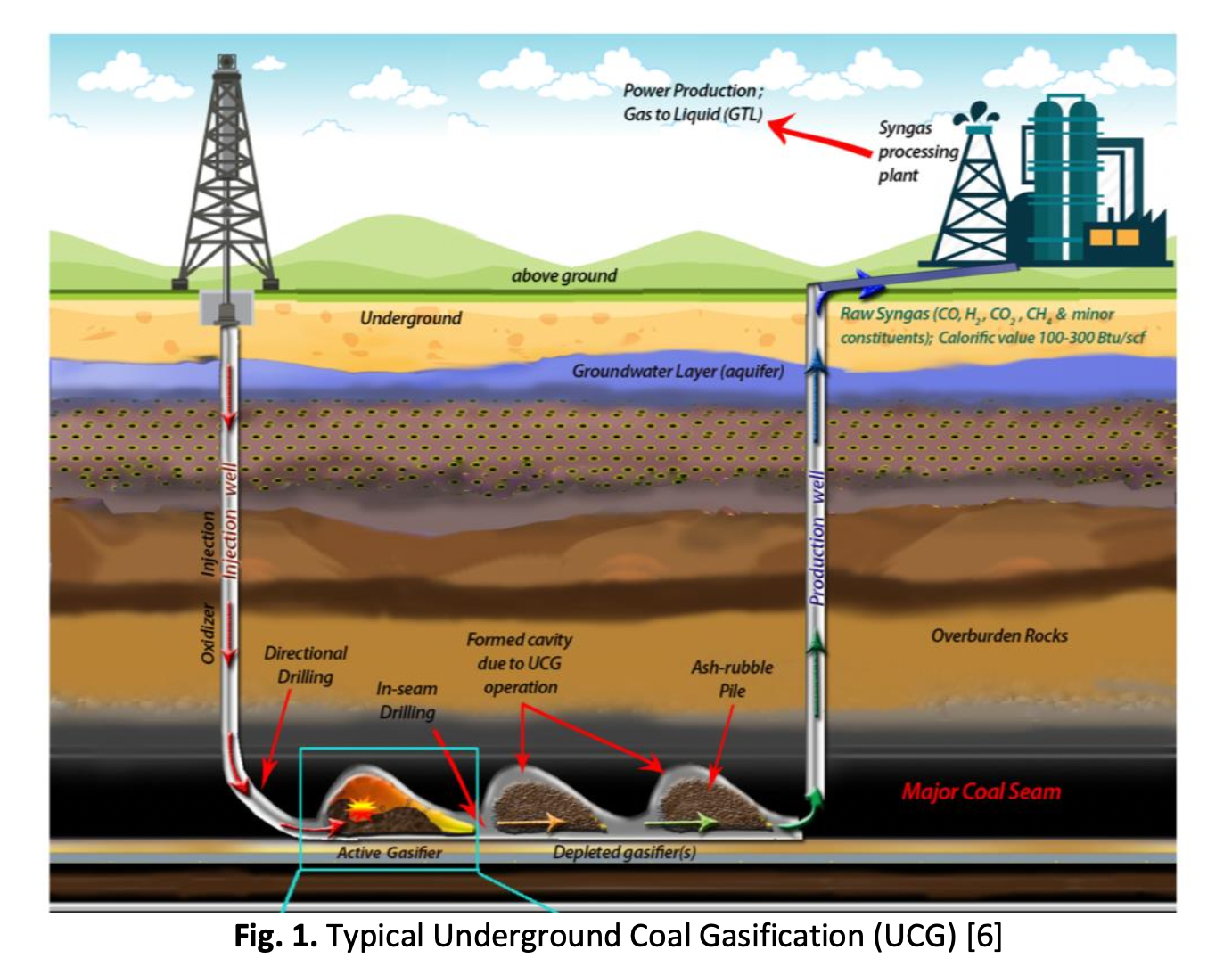

In this work, the process of Underground Coal Gasification (UCG) was studied experimentally and numerically. The typical cavity of UCG was a half-teardrop shape. The coal samples were collected from Mae Moh coal mine, Thailand. The coal type is mainly lignite. To generate the gasification process, the coal sample was heated in the half-teardrop cavity by injecting partial oxidant, which is air, according to the Equivalent Ratio (ER) of 0.1, 0.2, 0.3, 0.5, and 0.7. The properties of the product gas were measured using a syngas analyser. CFD technique, ANSYS (Fluent), was used to simulate flow characteristics and gasification process in the cavity. The experimental results show that the low heating value (LHV) of syngas peaks at 0.92 MJ/m3 when ER = 0.1, and LHV decreases monotonically as ER increases. The CFD results show that the area of high temperature in the UCG cavity is larger when the ER was greater.

Downloads