The Effect of Air Equivalent Ratio on Combustion and Gasification Process Characteristics of Oil Palm Biomass in Fluidized Bed Reactor

DOI:

https://doi.org/10.37934/arfmts.99.2.108118Keywords:

Combustion, gasification, numerical studies, mixed palm cakeAbstract

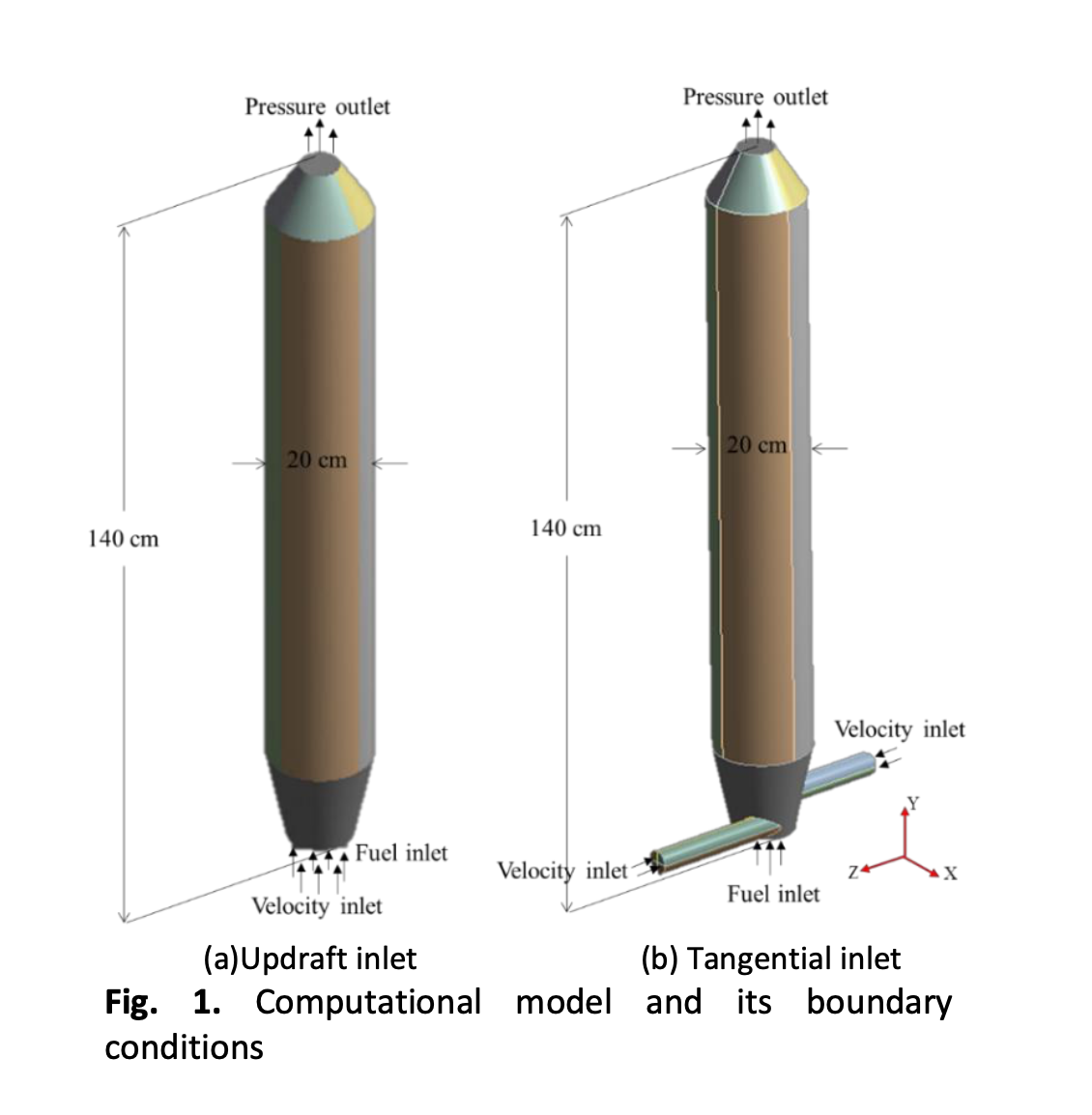

This study investigated the effect of air equivalent ratios (ERs) (0.1-5) on the temperature distribution in the fluidized bed reactor during gasification and combustion process. The cylindrical reactor with the diameter of 20 cm and height of 150 cm was used in this study. The conical shape connector was installed at the bottom of the reactor for different air supplying patterns, including tangential flow and up-flow. The mixed oil palm cake was used as a feedstock. The temperature distribution in the reactor during combustion and gasification process was observed by applying the numerical calculation using ANSYS software (Ver.19.0, Fluent) with 3D model. The effect of air supplying patterns and air equivalent ratios were then investigated. The results showed that the temperature distribution obtained from simulation was not consistent with the experiment results for an up-flow air supplying method. In the case of tangential air inlet, the results from simulation were similar to the experimental results. Consequently, these results will be the guideline for further studies of biomass gasification and combustion using fluidized bed gasifier with different inlet air patterns and ERs.

Downloads