Cost And Product Optimization of Upgrading Light Naphtha Using Pressure Swing Adsorption Method by Aspen Adsorption Simulation

DOI:

https://doi.org/10.37934/arfmts.100.2.198210Keywords:

Adsorption, economic potential, naphtha, Pressure Swing Adsorption, RON, simulationAbstract

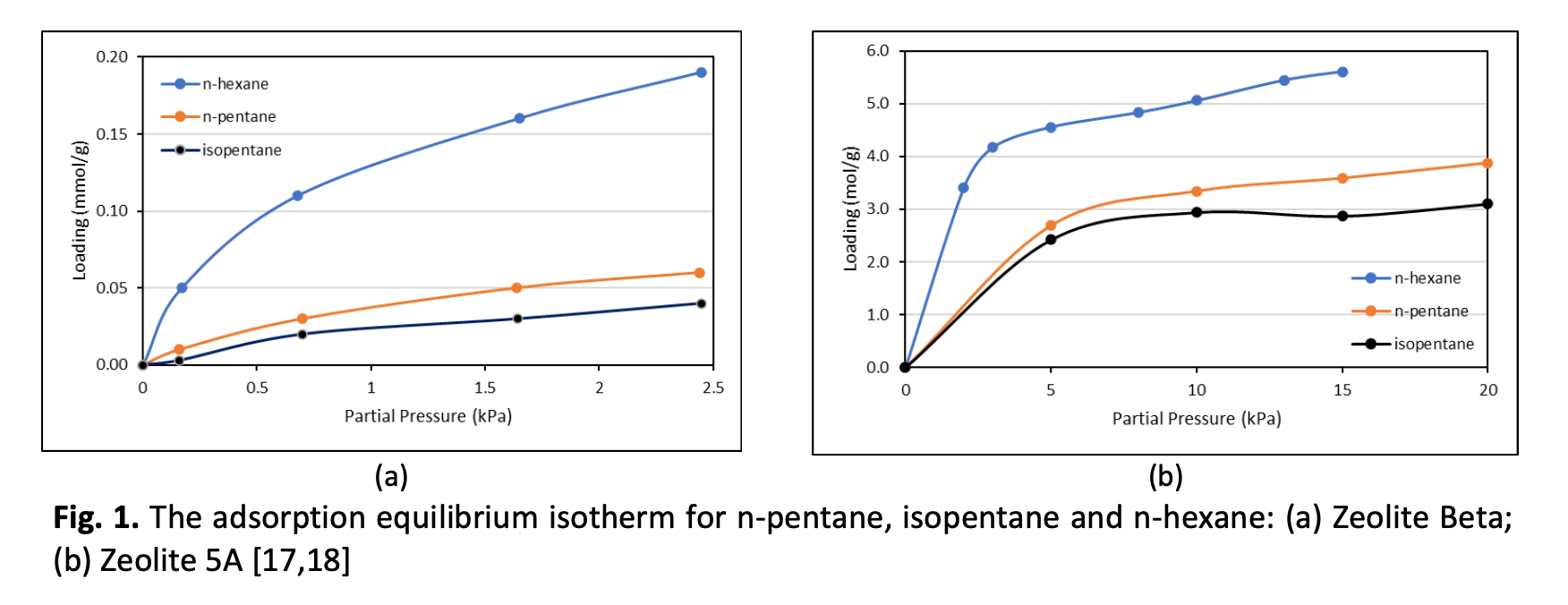

Light naphtha is an organic compound produced from the distillation process that is often sold at a low price because of its poor performance, especially in the value of Research Octane Number (RON). The goal of this study was to improve the quality of naphtha to become a useful fuel with qualifying performance that is High Optimum Mogas Component (HOMC) by using the Pressure Swing Adsorption (PSA) method with the help of Aspen Adsorption simulations to find the most optimal combination of zeolite adsorbents (Beta and 5A) to use in the process. The principle of this quality improvement is to separate the compounds contained in naphtha that have low RON values from those that have high RON values so that the performance of naphtha that has gone through the adsorption process can be maximized. For this study, the RON target from HOMC is 95, while the value of RON for feed light naphtha ranges from 61-65. There are three compounds simulated in this PSA process, n-pentane and n-hexane as compounds that want to be separated because they have low RON values from iso-pentane which has a high RON value. Furthermore, after acquiring the combination of adsorbents that resulted in the products that have the highest RON, the economic potential of all variables was evaluated to get the most optimal process to use. The economic potential is also analyzed to find the profit of the PSA process. The most optimal results are obtained when the adsorbent configuration produces the product with the highest RON and produces high economic potential. The results showed that the most optimal adsorbent combination is to use 30% Zeolite Beta; 70% Zeolite 5A with product results having the highest RON of 84 and economic potential of US$ 114,410,163.92.

Downloads