Preliminary Design of Mini Oil Refinery Plant

DOI:

https://doi.org/10.37934/arfmts.92.1.3950Keywords:

crude distillation, crude oil, economic, feasibility, mini refineryAbstract

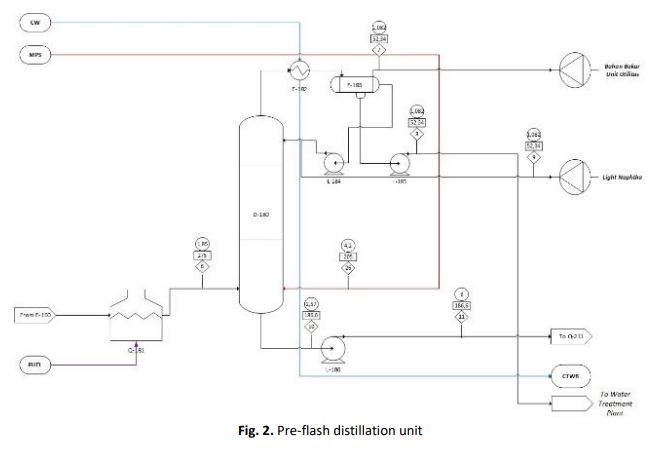

As an archipelagic country, Indonesia faces challenges in supplying fuel to various regions. Some regions have small oil reserves and small fuel demand. Other regions have greater fuel demands. One solution to overcome the issue of fuel supply is to build and develop mini refineries with a scale of 6,000 – 20,000 barrels per day to maximize the potential of existing oil reserves, reach remote areas, and meet domestic demands. This study aims to analyze the feasibility of a mini oil refinery from a technical and economic perspective. The feed used for this plant is light crude oil with API gravity 47.3002 from the Belida block, South Sumatra. The plant is designed with a capacity of 10,000 barrels per day to produce intermediate products. The production process at this plant uses a simple process to reduce capital costs, which consists of a Preheater, Pre-Flash Distillation Unit, Atmospheric Distillation Unit, and Vacuum Distillation Unit. From the results of economic analysis, the obtained capital cost of IDR 517,640 million and operational cost of IDR 2,860,622 million. Meanwhile, the payback period is 4.5 years, and the break-even point is 48%. By considering the economic and technical aspects, this Mini Oil Refinery is feasible to be built.

Downloads