A Numerical Simulation under Milk Fouling in A Plate Heat Exchanger in the Presence of a Porous Medium

DOI:

https://doi.org/10.37934/arfmts.91.1.117Keywords:

PHE, milk heat treatment, fouling model, dynamic and thermal aspects, fluent code, CFDAbstract

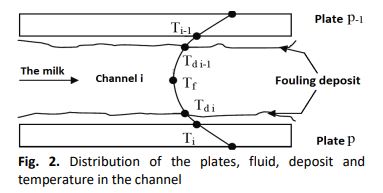

Fouling is a known dairy industry issue during thermal treatments using a plate heat exchanger (PHE) it directly affects not only energy costs and maintenance but also production, energy and water losses during cleaning operations. Therefore, a considerable attention has been paid to the modelling of the fouling phenomena in order to improve the PHE performances. In this paper, a mathematical model describing the steady state was established for the flow at the macroscopic scale; the model account for constant and turbulent flows between two flat parallel plates at imposed temperature in the presence of a porous medium. The closure k-ε model has been chosen and the conservation of equations has been developed. The numerical procedure adopted was based on the finite volume method on the Fluent CFD software. The accuracy of the Fluent software was validated by comparing our results with those previously published in the literature. The numerical results showed a good reliability of the developed code for both laminar and turbulent regimes of the studied phenomenon. It was able to capture the dynamic and the thermal aspects of the process. The maximum velocity at the output of the channel increased when the thickness of the porous medium was increased. An increase of the average temperature over the whole length of the channel was observed; while a decrease of the average temperature at the outlet of the channel was noticed. The deposit fouling caused additional thermal resistance. Finally, a decrease of the temperature gradient and Nusselt number in the medium of the channel was observed.

Downloads