Experimental Study on the Effect of TiO2–Water Nanofluid on Heat Transfer and Pressure Drop in Heat Exchanger with Varying Helical Coil Diameter

DOI:

https://doi.org/10.37934/arfmts.107.2.5067Keywords:

Helical coil, Nusselt number, heat exchanger, varying diameter, nanofluid, Dean number, friction factorAbstract

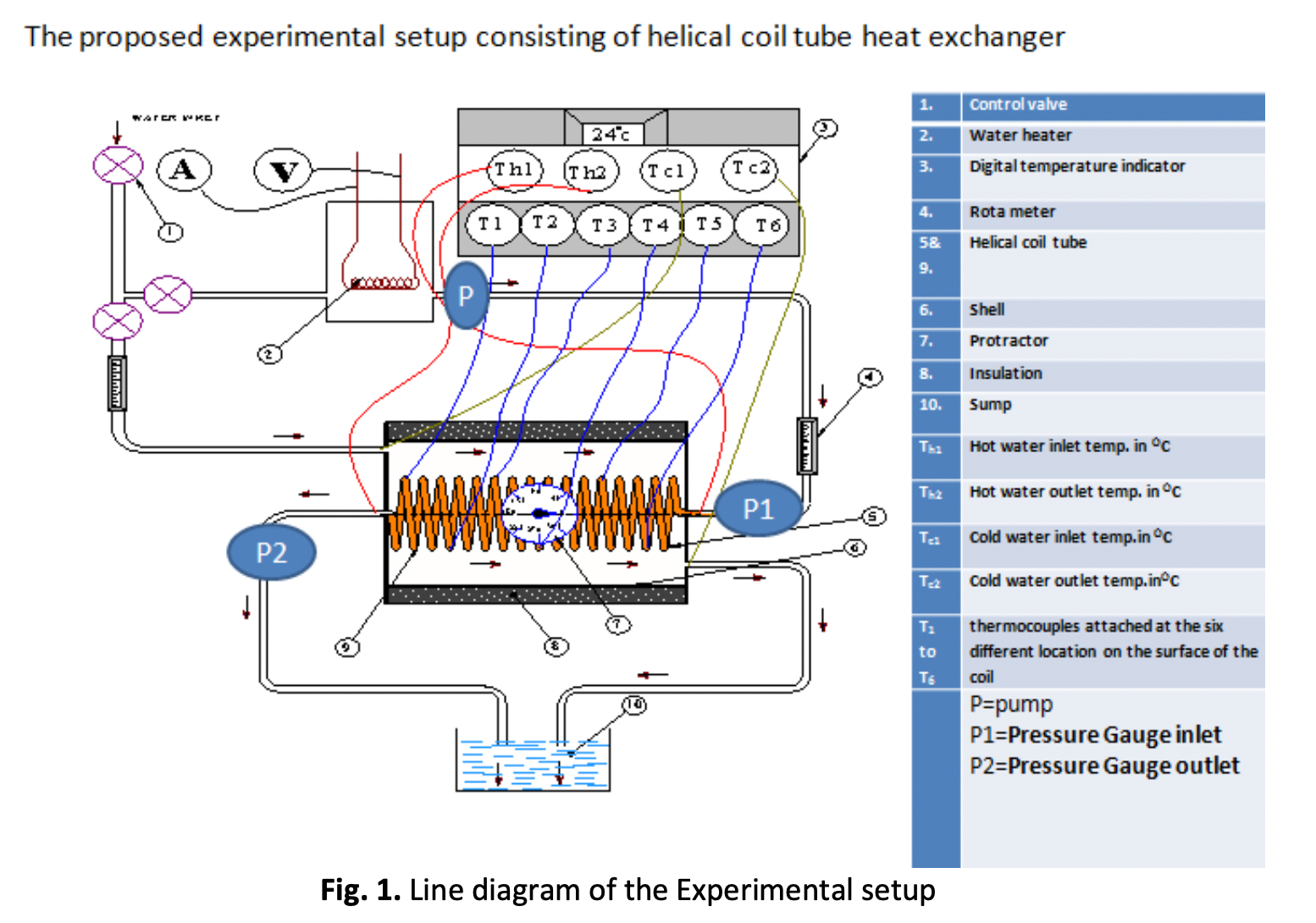

The growing demand for efficient heat exchangers has promoted extensive research in exploring advanced heat transfer fluids and novel geometries. This paper investigates the heat transfer and pressure drop characteristics in helical coil heat exchanger employing water-based TiO2 as nanofluid. The utilization of nanofluids offers promising enhancements in thermal conductivity and convective heat transfer in heat exchanger applications. The effect of nanofluid concentration and flow rate on heat transfer and pressure drop with varying helical coil diameter performance is investigated. Experimental tests were conducted using a heat exchanger with different helical coil pipe diameters of 9.53mm, 12.7mm and 15.88mm with constant pitch of 30mm and varying concentrations of TiO2 nanoparticles in water (ranging from 0.1% to 0.5% by volume). The heat transfer coefficient and pressure drop were measured at different operating conditions. The results shows that the addition of TiO2 nanoparticles to water significantly enhanced the heat transfer performance in the helical coil heat exchanger. There is an enhancement in heat transfer coefficient with increasing nanofluid concentration and with increase in pipe diameter. The maximum enhancement in heat transfer coefficient is observed at nanofluid concentration of 0.5% and for pipe diameter of 15.88 mm. However, there is increase in pressure drop with increase in nanofluid concentration and with decreasing pipe diameter. The pressure drop found to be higher for nanofluids compared to pure water. The maximum pressure drop is observed at a concentration of 0.5% and for pipe diameter 9.53mm. In conclusion, the use of a water-based TiO2 nanofluid in a helical coil heat exchanger offers improved heat transfer performance compared to pure water. However, the pressure drop also increases with nanofluid concentration and decreasing pipe diameter. Therefore, a trade-off between heat transfer enhancement and pressure drop should be considered in the design and operation of such heat exchangers.

Downloads