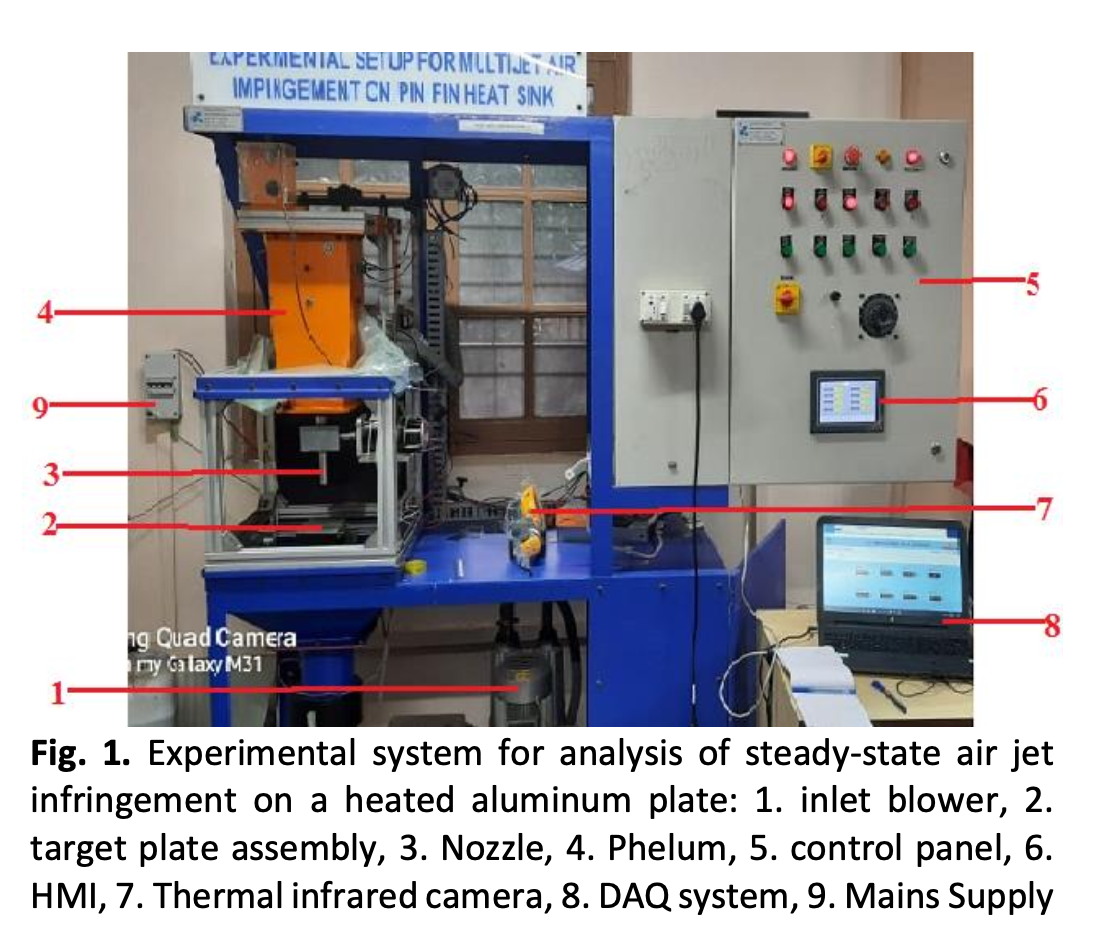

Experimental Investigation of Local Nusselt Profile Dissemination to Augment Heat Transfer under Air Jet Infringements for Industrial Applications

DOI:

https://doi.org/10.37934/arfmts.112.2.161173Keywords:

Nusselt number, Reynolds number, IR cameraAbstract

An experimental study is presented in this paper to evaluate the enhancement of heat transfer characteristics. This includes the study of a steady air jet impinging on a planar aluminum plate with constant heat flux. Extensive industrial applications of heat transfer include electronic heat sinks, the food industry, automobiles, and heat exchangers. The magnitude of the local Nusselt number along the streamwise direction is determined through detailed experimental computation using the infrared radiometry technique. The range of Reynolds number was selected between 6500 ≤ Re ≤ 15000 and the air jet outlet-to-target surface spacing 2 ≤ Y/D ≤ 6. The objective is to develop a semi-empirical correlation that can be used to determine the distribution of local Nusselt numbers over a flat plate. Considering the objective function of the spacing between the air jet outlet and target surface spacing (Y/D), Reynolds number (Re), and non-dimensional number from stagnation point in the radial direction of the plate (r’/D), it was observed that the heat transfer rates are higher for the configuration Y/D = 4 for varying Reynolds numbers, a 5 percent increase was observed. The stagnation Nusselt number shows an increasing trend up to Y/D = 4, for Reynolds numbers 10,000 and 12,000 respectively, the corresponding stagnation Nusselt numbers are 110 and 115. In comparison to the stagnation Nusselt number, which is the same Reynolds number corresponds to, the transition field Nusselt number had heat transfer values that were 12% lower.

Downloads