Thermodynamic Performance of an Engine by Modifying Piston Bowl Geometries Fuelled by SME-100, LA-100, KB-100 Biodiesel Blends, and Diesel

DOI:

https://doi.org/10.37934/arfmts.102.1.113Keywords:

Combustion performance, diesel engine, thermodynamic performance, Roselle-biodiesel, Karanja-biodiesel, Soybean-biodiesel, modifying piston bowl geometryAbstract

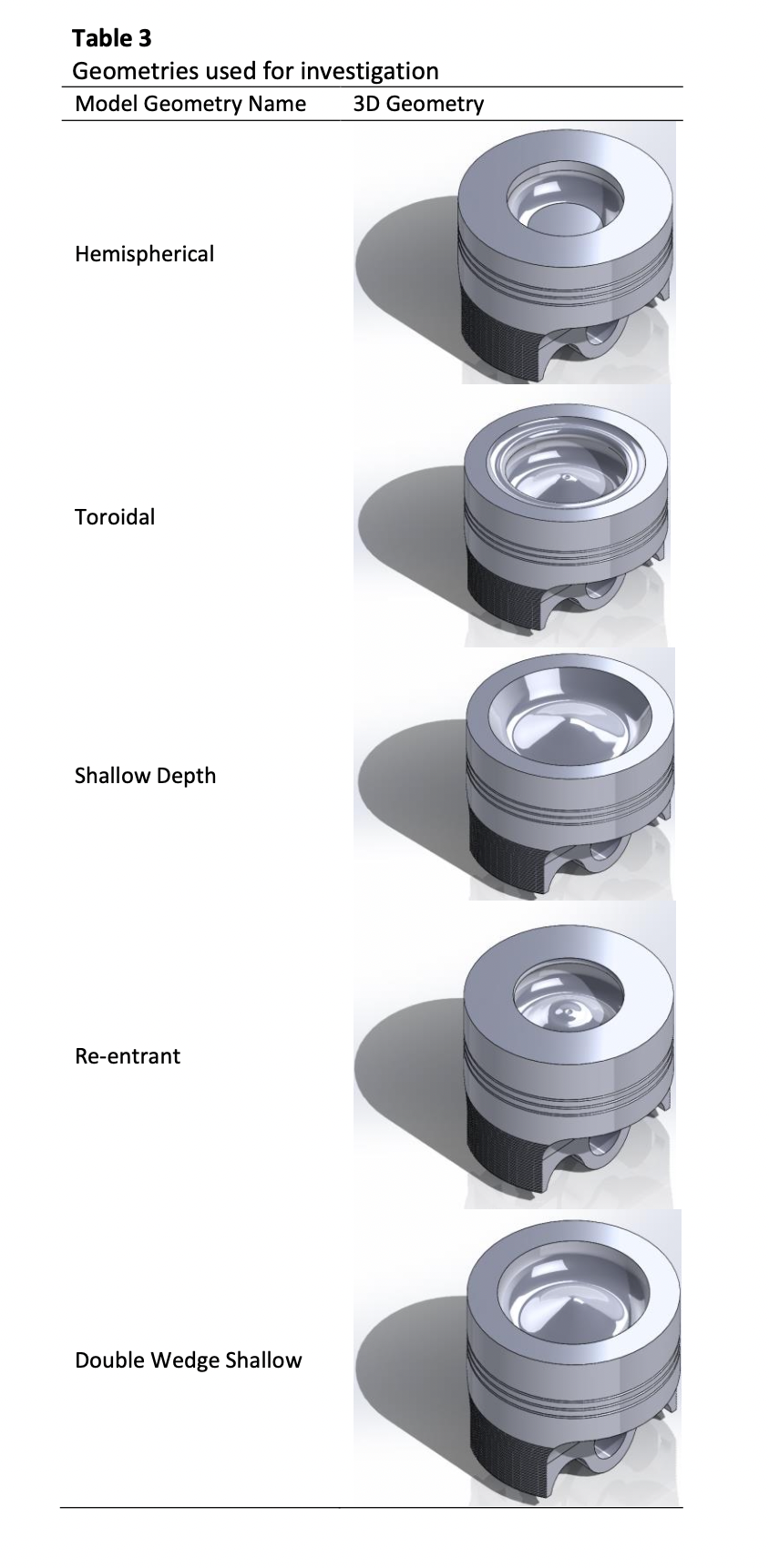

Simulation of Direct injection (DI) compressed ignition (CI) engine working on diesel thermodynamic cycle on diesel-Rk software carried out for evaluating the effect on thermal performance. The analysis of an engine was worked out by applying different bowl geometrical shapes and by testing with different fuels. Further same compositions were tested on an experimental test rig having a set-up of (compressed ignition, single cylinder, four strokes, air-cooled, direct injection) diesel engine at constant crank speed. Hemispherical (HCC), Shallow depth (SCC), Re-entrant (RCC), Double wedge shallow, and Toroidal (TCC) piston geometries were created in solid-work and analyzed with B-100 blend of SME (Soybean Methyl Ester), KB (Karanja Biodiesel), LA (Roselle Biodiesel) and diesel further they were analyzed and their effects have investigated experimentally and numerically at fully loaded condition, with a constant crank speed of 1500 rpm and by setting constant compression ratio at 17.5. BSFCs were higher by 21.03%, 12.97%, and 12.96% for SME100, KB100, and LA100 with hemispherical, toroidal, and re-entrant type combustion chambers compared with the diesel fuel. Indicated thermal efficiencies and ignition delay periods were reported slightly lower for different blends and pure biodiesel than diesel at specific load conditions whereas combustion durations were reported higher compared to diesel.

Downloads