Review Analysis on CFD Techniques and Numerical Methods for IC Engines Fueled with Diesel and Biofuels

DOI:

https://doi.org/10.37934/arfmts.110.1.4062Keywords:

CFD, Turbulence, IC Engine, Biodiesel, Combustion ChamberAbstract

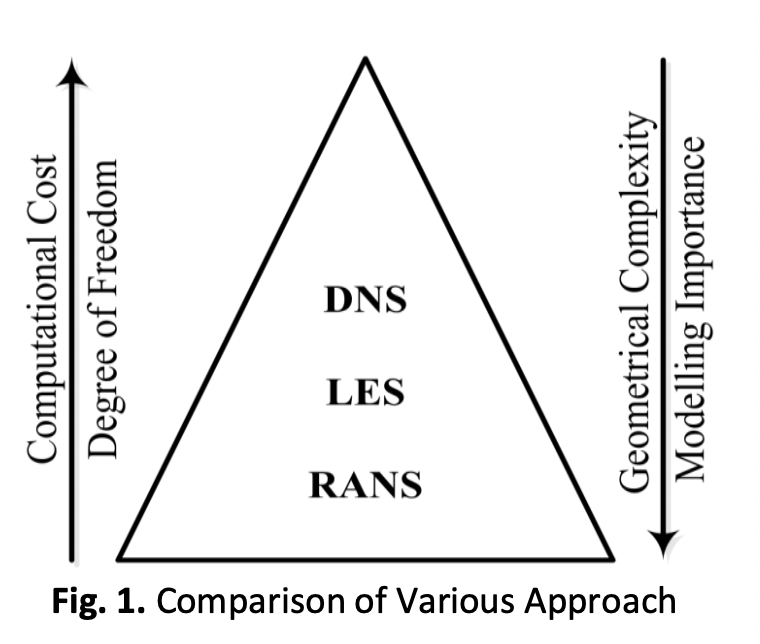

Over the years, there has been a drastic reduction in petroleum-based fuel stocks and stringent emission requirements for internal combustion engines by environmental authorities around the world. A marginal improvement in efficiency and emissions shows significant benefits. Fluid motion within the combustion chamber plays a vital role and is considered a crucial parameter for controlling the combustion process. The fuel supply system or induction system of the Spark Ignited engine prepares and controls air-fuel mixing. The system in the SI engine is capable of generating bulk motion and turbulence prior to the ignition process. In the CI engine Induction system (Swirl and Tumble), the shape of the chamber (Squish) controls the path and quality of air whereas the diesel injection system controls Spray characteristics (Penetration, Atomization, Break-up, and Evaporation of Spray). During the last three decades, a lot of efforts have been made by researchers to develop multidimensional fluid dynamics codes for the prediction of flow in an engine for reducing engine development time and cost. To be a more trusted and acceptable tool, the results of numerical analysis of the combustion chamber. and its fluid dynamics have to show accuracy in the prediction of emission standards and combustion parameters by taking the minimum possible time. This article reviews the methods and results of numerical analysis and CFD results of CI engines run on diesel and biofuels. It also reviews results and their accuracy for different CFD.

Downloads