Melting Characteristics of Hybrid Nano Enhanced Phase Change Material in a Finned Circular Tube

DOI:

https://doi.org/10.37934/arfmts.102.1.3750Keywords:

Finite volume method, hybrid nanoparticles, high temperature PCM, spherical shaped nanoparticlesAbstract

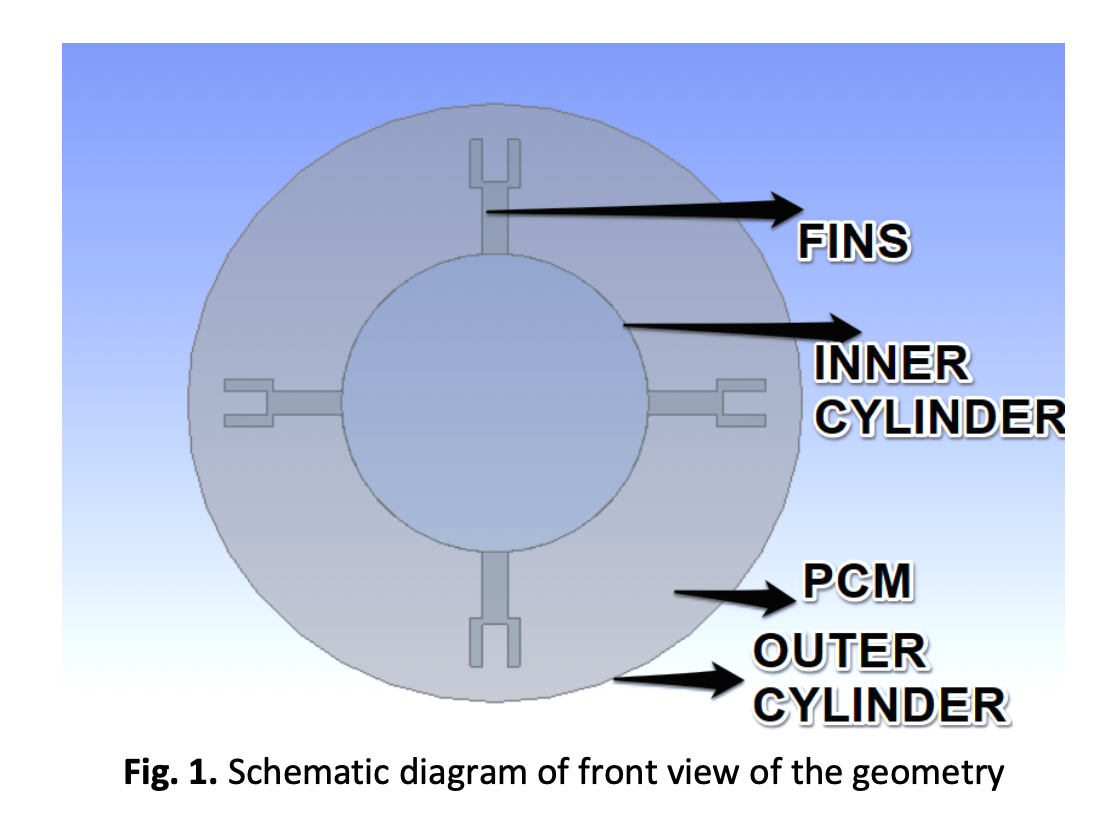

In this study, the melting characteristics of hybrid nano-enhanced phase change material in a finned circular tube were studied by using the Finite volume method. This setup of circular tubes with a phase change material is used as cooling systems in automotive industries, air-conditioning, refrigerators, and other applications of cooling systems. There is a need for enhancing the specific heat capacity of this system to ensure that the system works even at high temperatures. As the current problem includes many design parameters and boundary constraints, the finite volume method has been performed to obtain a detailed report and data to examine the deformation of the hybrid nanoparticles and heat transfer rate on the corresponding surface. The current paper reviews and focuses mainly on the high-temperature PCM. And the suitable PCM has been selected based on its limitations and properties. To ensure the increased specific heat capacity, a salt-based phase change material, i.e., a mixture of NaNO3-KNO3 (60:40 ratio) binary salt. This PCM could hold a temperature up to 334◦C before melting to change its phase. In addition to spherical-shaped nanoparticles of silica (SiO2) in this binary salt, it tends to have a significant potential for enhancing the thermal storage characteristics of the NaNO3-KNO3 binary salt. On an extended surface, Finns are used on the peripheral of the circular tube to increase the surface area, which leads to an increase in frictional resistance resulting in a reduced airflow rate in the vicinity of the finned surface. From case studies, it has been found that the optimum fork-shaped fin array with two branches gives higher heat dissipation than the optimum rectangular fin. In the majority of the cases, the optimum fork-shaped fin array gives a 59.9% higher heat transfer rate compared to the rectangular fin array. Thus, the melting characteristics of the hybrid of NaNO3- KNO3 with nanoparticles of silica are studied when placed in a circular tube containing fork-shaped fins.

Downloads