Influence of Leading and Trailing Edge Angle on Impeller Blades of a Pump as Turbine

DOI:

https://doi.org/10.37934/arfmts.105.1.166183Keywords:

Impeller, hydraulic efficiency, pump as turbine, leading edge, trailing edgeAbstract

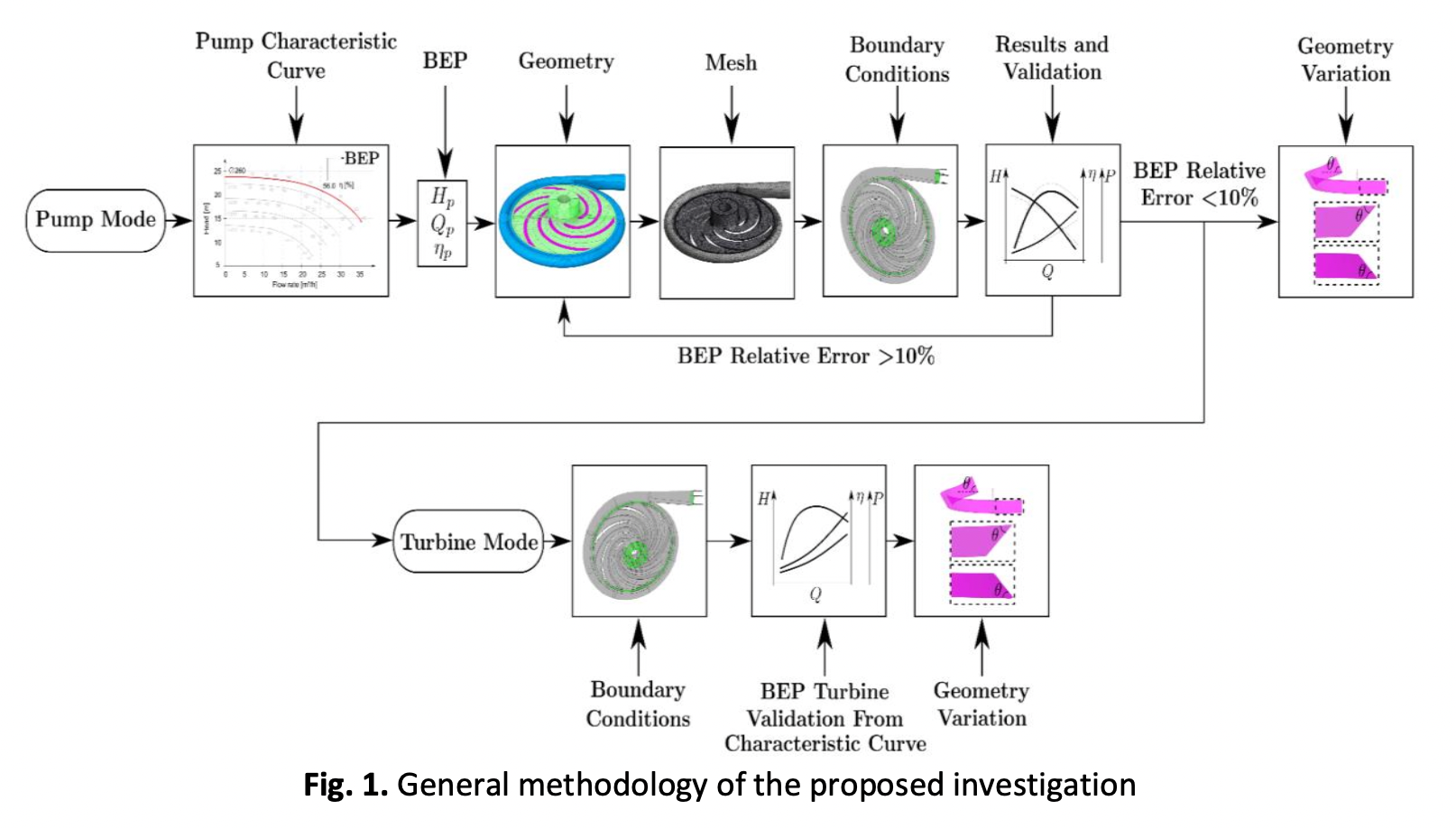

A pump as turbine (PAT) is a turbomachine that converts hydraulic energy into electricity. One of the study topics in PAT is the efficiency due to centrifugal pumps are not designed to operate in reverse mode. Geometric variations of the impeller have been studied in the literature. However, it was not possible to evidence the influence of the inclination of the blade leading and trailing edge. Therefore, the objective of this work is to analyze numerically and fluid dynamically the inclination angle of the blade leading and trailing edge of a centrifugal pump, in pump and turbine mode. First, the characteristic curve was validated. Then, the inclination of the leading and the trailing edge was modified, in a range of 25° to 90°, obtaining head, efficiency, and power graph. As a result, in pump mode was evidenced that an angle close to 90° on the blade trailing edge provides a higher efficiency of 50.26% and decreases until 40.77% when the angle approaches 30°, reducing the head to around 20%, while power remained constant. In turbine mode, an inverse effect was obtained, where the maximum efficiency was 60.9% and the generated power increased up to 4.76 kW in the blade leading edge. Therefore, the angular variation of the leading and the trailing edge is adequate in turbine mode, while in pump mode there is a loss of capacity.

Downloads