Parametric Study of Photovoltaic System Integrated with Organic Phase Change Material using ANSYS

DOI:

https://doi.org/10.37934/arfmts.106.1.7689Keywords:

Crude palm oil, Phase Change Material, PV-PCM, Photovoltaic, simulationAbstract

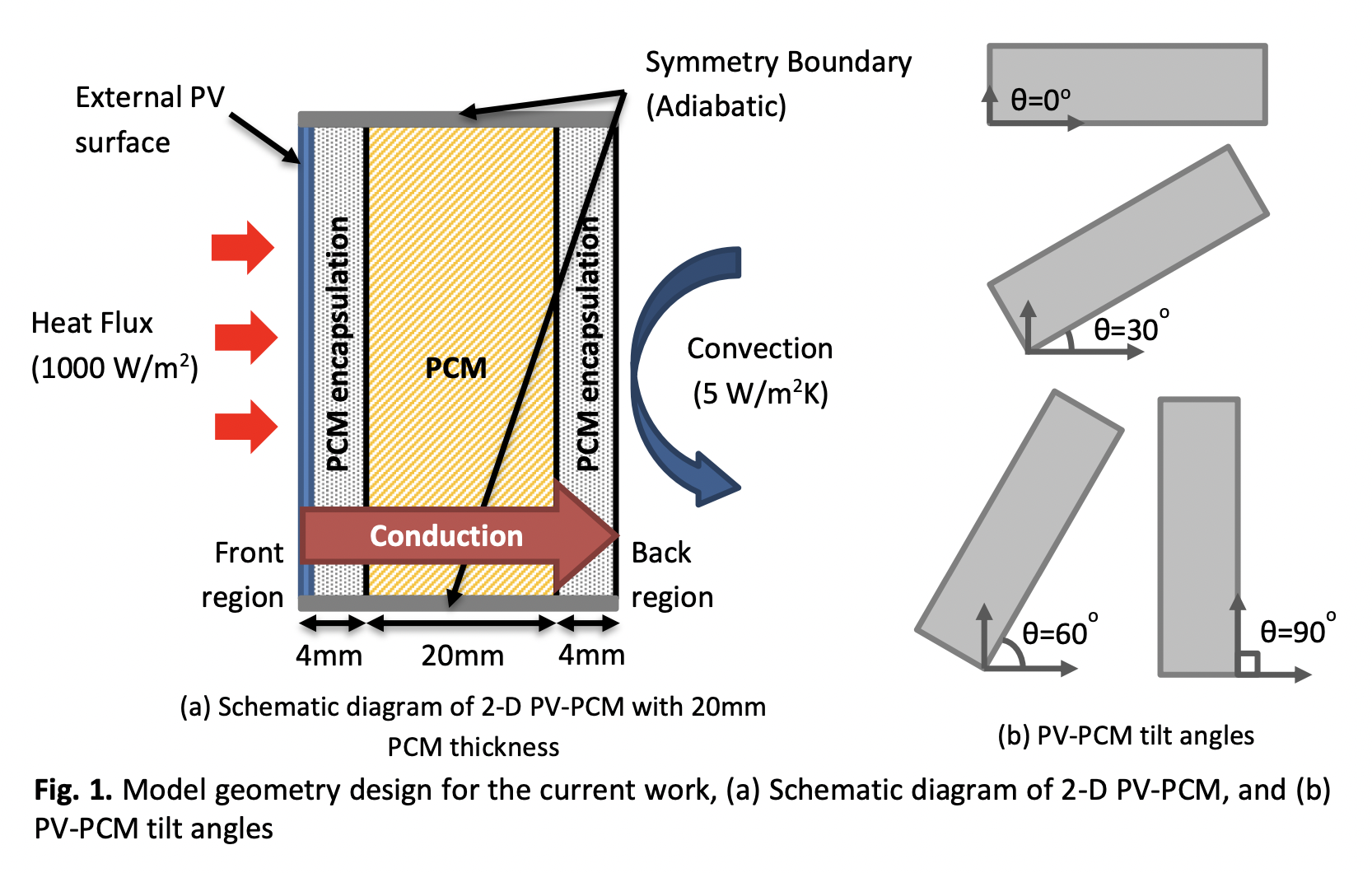

Thermal management is essential in photovoltaic (PV) systems for enhancing PV performance. Passive cooling with a phase transition material (PCM) is one method for managing overheated PV. Crude palm oil (CPO) is preferred in Malaysia since it is both sustainable and inexpensive. To assess the feasibility of CPO as a PCM, a parametric analysis focusing on the PV-PCM tilt angles, PCM thickness, and PCM encapsulation material was carried out numerically. ANSYS computational fluid dynamics software is used in this work. The two-dimensional model is used to simulate a monocrystalline PV surface with macro-encapsulated PCM placed among two aluminium layers. Each parametric analysis's temperature distribution on PV surfaces and temperature contour for PV-PCM for tilting angle and PCM thickness are also discussed. Validation work was also performed with 9.73% errors that were within the allowed range. The result reveals that when the tilt angle is near-vertical (90o) the natural convection flows more rapidly. The system's average front surface appears to achieve the melting point completely faster. The optimum thickness for CPO to perform is 80mm, which can store heat for around 4000s (66.67mins). Aluminium outperforms stainless steel and copper as a PCM encapsulant since it facilitated the melting process by absorbing more heat. CPO with 80mm thickness, aluminium encapsulated, and vertical orientation has significant potential for thermoregulation in systems, especially in Malaysian weather (27oC).

Downloads