Investigation of Thin-Layer Drying of Coffee Beans Using a Double-Condenser Compression Refrigeration System: Effects of Air Mass Flux, Specific Humidity and Drying Temperature

DOI:

https://doi.org/10.37934/arfmts.106.1.90103Keywords:

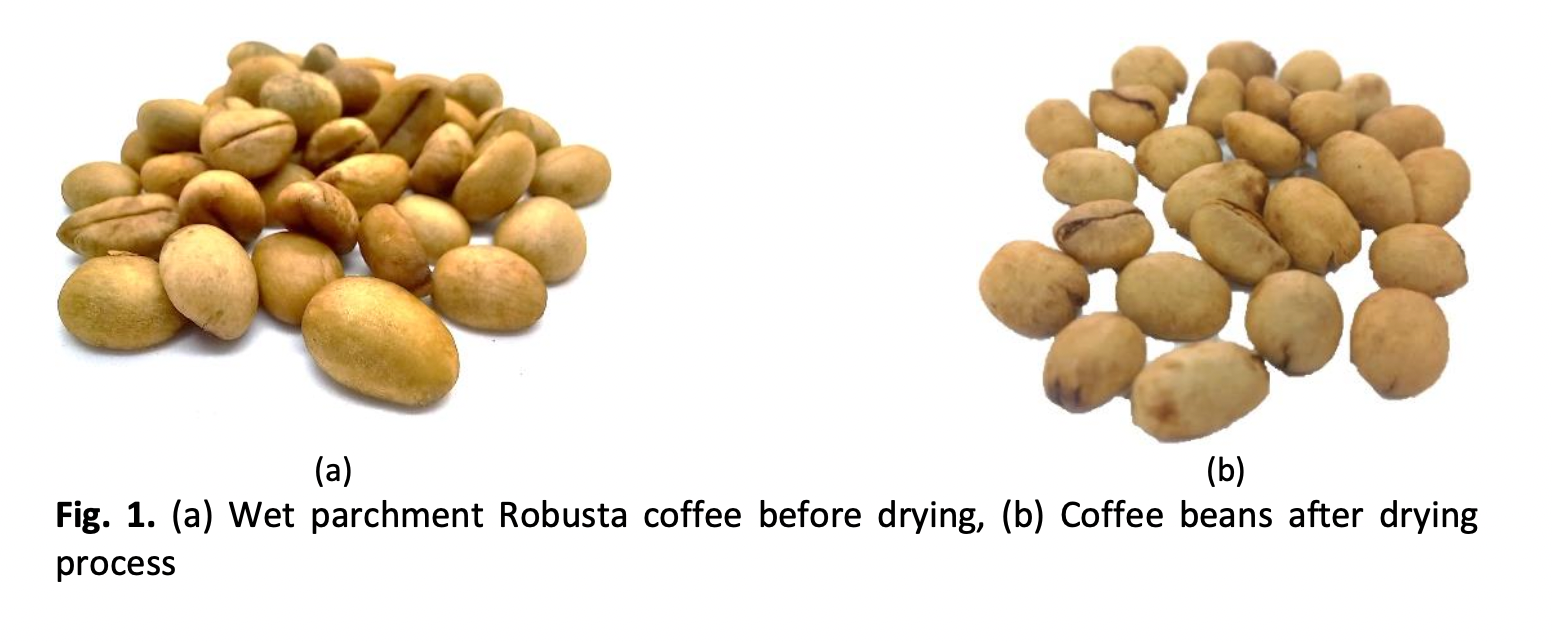

Robusta, Coffee beans, parchment coffee, drying rate constant, activation energyAbstract

The drying process is the key to the quality of the coffee produced. The allowable moisture content of coffee beans is 12%. The air mass flux, specific humidity, and the drying temperature are varied using a bed dryer drying system combined with a double condenser refrigeration system. Robusta coffee beans are used in this research to obtain the characterization of coffee beans. The highest drying rate constant is obtained by 2.44 × 10-4 s-1 directly proportional to the increased air mass flux and drying air temperature, with a value of 1.701 kg/s m2 and 80 °C, but inversely proportional to the specific humidity, with a value of 7.01 g/kg d.a. The lowest activation energy value was 31.88 kJ/mol when the air mass flux was 1.701 kg/s m2, the drying air temperature was 80 °C, and the average specific humidity was 7.01 g/kg d.a. In this work, the developed correlation is proposed to practically predict the activation energy (EA) and the pre-exponential factor (A) with equation and respectively. Based on Ea and A correlation equation, it can be used for designing a bed dryer type coffee drying system for a larger scale.

Downloads