Thermodynamic Simulation in Eco-Friendly Aquadest Production through Compression System Method Combined with Steam Power Plant as Heat Source

DOI:

https://doi.org/10.37934/arfmts.100.1.6376Keywords:

Aquadest production, compressor, power plant, water, desalinationAbstract

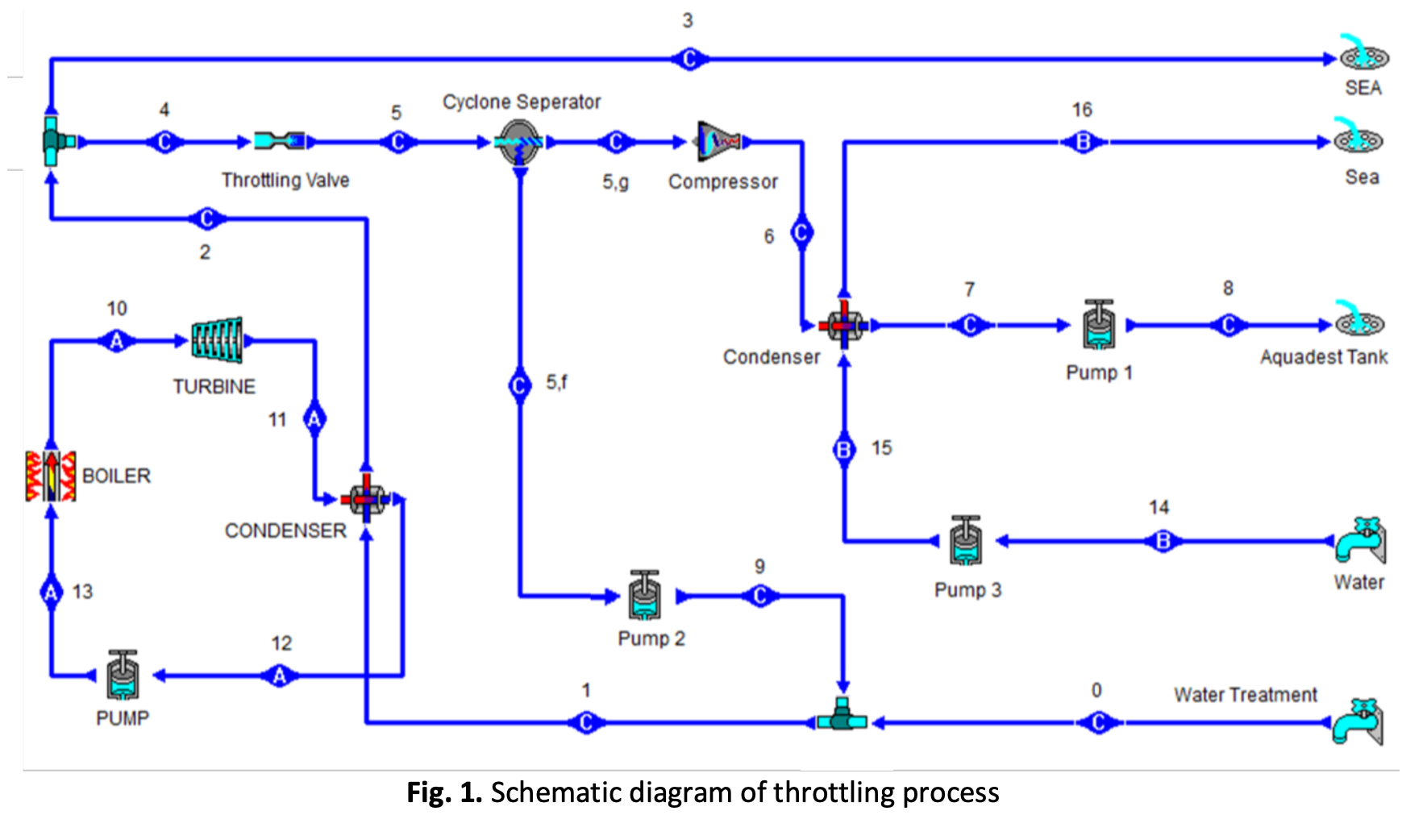

Access to clean water and sanitation is one of the Sustainable Development Goals (SDGs), a global action plan agreed upon by world leaders. Water demand is increasing every year. As much as 97% of the water on earth is seawater, which requires desalination technology to convert seawater into freshwater that will be used to meet daily human needs. It is necessary to continue to develop environmentally friendly clean water treatment technology to overcome the problem of freshwater crisis. Research related to clean water treatment technology needs improvement in order to have a high effectiveness value to be applied and developed in areas with clean water crisis. Therefore, this study aims to produce distilled water by utilizing heat from the condenser of a steam power plant. The cooling water from the condenser must first be throttled to allow the vapor and liquid extraction to occur. Next, the steam is compressed to raise the temperature. After the compression process, the steam must be condensed using a water-cooled condenser to produce the distilled water in order to get maximum distilled water yields and low energy consumption. In this study, the lowest SEC (Specific Energy Consumption) was -1194.02kJ/kg of distilled water with the mass flow rate of 0.996 kg/s. To overcome the environmental problems, the condenser temperature was lowered to 41.5°C, and the PPTD (Pinch Point Temperature Difference) by 10 made the temperature discharge to seawater drop to 31.5°C. The lowest energy consumption can be obtained by setting the temperature in the cyclone separator to 22°C and the mass of water discharged to the sea by 99%, which lowers compressor energy consumption.

Downloads