Prediction of Fluid Pattern of Biodiesel Production in a Membrane Reactor

DOI:

https://doi.org/10.37934/arfmts.111.1.156165Keywords:

Biodiesel, membrane reactor, Computational Fluid Dynamic, renewable energy, separation, fluid patternAbstract

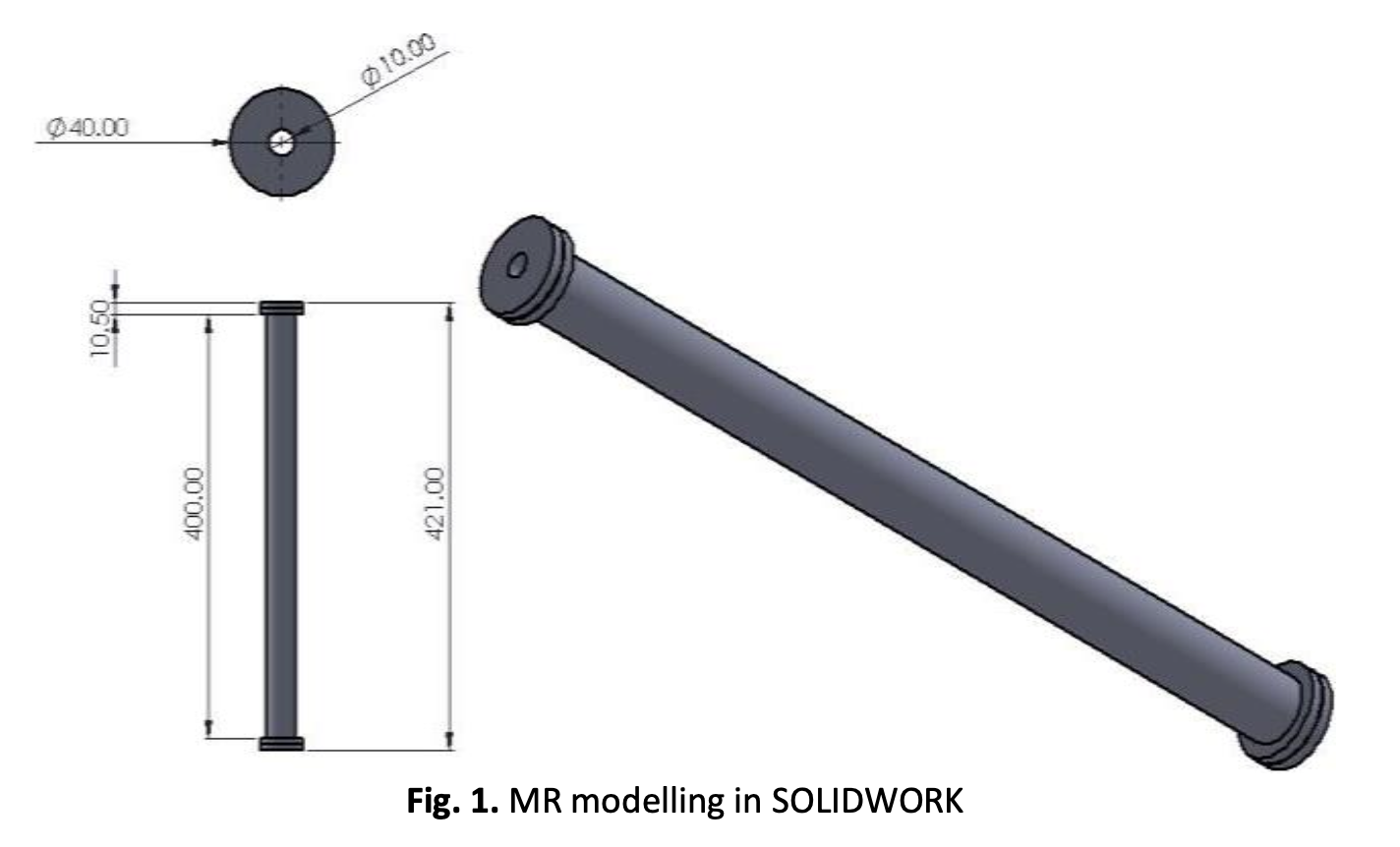

Utilization of membrane reactors for biodiesel production has been an alternative to conventional batch reactors. The membrane in the reactor acts as a separation layer, preventing the formation of by-products and allowing the desired biodiesel product to pass through. This can improve yields and reduce waste, making the process more environmentally friendly and economically viable. This study aimed to analyze the fluid flow and velocity profile inside the membrane reactor and determine the volume fraction of biodiesel. The modeling and simulation of the fluid flow of biodiesel in a membrane reactor was carried out using SOLIDWORK and ANSYS software. Using a Eulerian-Eulerian two-fluid model, multiphase simulations were carried out. Three different temperatures, 333 K, 338 K, and 343 K, were used in the simulation. The results have found that at 333K, the biodiesel production in the membrane reactor shows the best flow characteristics compared to reaction temperatures of 338 K and 343 K. Additionally, the highest volume fraction can be predicted at the temperature of 333K. Further research and simulation study can be implemented to explore the effects of inlet velocity and reaction time on the fluid flow pattern of biodiesel inside the membrane reactor.

Downloads