Performance, Exhaust Emissions and Optimization Using Response Surface Methodology of a Water in Diesel Emulsion on Diesel Engine

DOI:

https://doi.org/10.37934/arfmts.93.1.112Keywords:

Response Surface Methodology, water in diesel emulsion, Diesel engine, Performance and emission, Nitrogen OxideAbstract

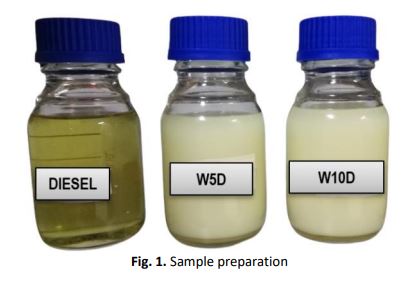

The use of water in diesel is an alternative to counteracting the increase in nitrogen oxide (NOx) emissions from diesel engines. However, some other criteria such as combustion performance and thermal efficiency were slightly reduced due to the impact of water content in diesel fuel. In other words, optimizing the balance between engine performance and emissions has always been a major problem in automotive industries. The purpose of this article is to demonstrate the use of RSM (response surface methodology) to improve the performance and emissions of a compression ignition (CI) engine which works on 5%, and 10% water mixes dubbed WD5 and WD10. This mixture of water emulsion to diesel is produced by using emulsifier ultrasonic. Tests were then performed on the Isuzu 4JJ1 4-cylinder 3000cc test bed engine with water cooled. Changes to engine load 20% to 50% and speeds of 1000rpm to 3000rpm. Experimental results data is then included in the Design Expert software to analyze the performance, emissions and optimization values using CCD Techniques in RSM. In performance analysis, pure diesel and WD5 are comparable with respect to power, heat efficiency of brakes and brakes of certain fuel consumption (BSFC). At higher loads, increased BTE levels and a neat BSFC drop were found. However, the combustion period is shorter. NOx and CO data slightly decreased with the same increase in water percentage at the same engine speed and load. However, the CO2 data showed a sharp increase with the increase in water content in fuel. Optimum engine operating parameters found as 5% water ratio, 50% of load and 2446 rpm while the best output parameters found as 103.7 Nm. of torque, 26.3 kW power, 43.8% BTE, 172 g/kWh BSFC, 521.8ppm NOx and 3.1% of CO.

Downloads